Fire hazards in the jumbo roll production process and how to protect your process with a high-tech solution.

Firefly has conducted a series of tests with various manufacturers of tissue paper to determine the risk of fire during the production of a jumbo roll and how different factors contribute to the generation of these fires.

The tests were performed taking into account those jumbos rolls in which the WebScan detected superheated particles. These overheated particles were a product of dust that came off the yankee hood and fell on the sheet, plus sparks that were generated in the creping blade area.

The results of these tests show that the following factors are crucial to increase or decrease the risk of fire in a jumbo roll:

- Fiber Type

- Paper Basis Weight

- Structure of Paper

- Tension at which the paper is being coiled

- Paper Machine Speed

- Temperature at Yankee Hood

- Additives used in paper

- Moisture content

However, the factor that contributes the most to the appearance of sparks and hot particles is the speed of the paper machine, at higher speeds (>1 600m/min) the detection frequency increases more than twice. The origin of this phenomenon is that any imbalance in the contact points between the Yankee roll and the creping blade, or overheated surfaces will create sparks or overheated particles with more energy due to the effects of friction.

It is also noted that at equal speeds the double-width machines generate more detections. The cause of this behavior could be traced to the splitter system.

In terms of overheated particles falling onto the sheet, those machines with enclosures had a higher number of detections. This is due to the fact that the particles that used to go out into an open space are now concentrated in the enclosure area, which makes them more susceptible to overheating and coming into contact with the paper sheet.

General conclusions of the study of fire hazards in the jumbo roll production process:

- At high operating speeds of the machines, episodes in the WebScan detection system increase.

- The origin of superheated particles is intrinsic to the operation of a paper machine, good practices may reduce their incidence but not eliminate them entirely. It is very important to note that most superheated particles will not emit light but have the potential to generate a fire.

- The new machine design with enclosed sections to keep dust from escaping to the rest of the plant, while decreasing dust accumulation in some areas, increases the risk of fire in the paper machine.

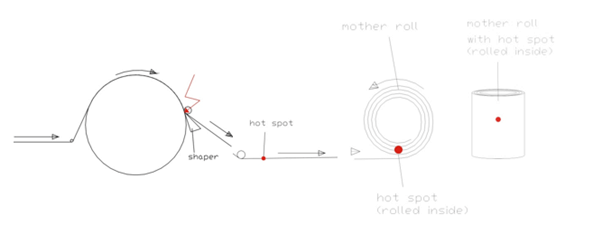

- Once the jumbo roll has been produced it is difficult to identify which of them may generate a fire due to the radiation absorption properties of the paper. This means that thermography-based methods do not identify a fire until it is too late.

- The paper itself encapsulates the overheated particle, which means that this particle can generate a fire in any direction inside the coil.

How to protect your process?

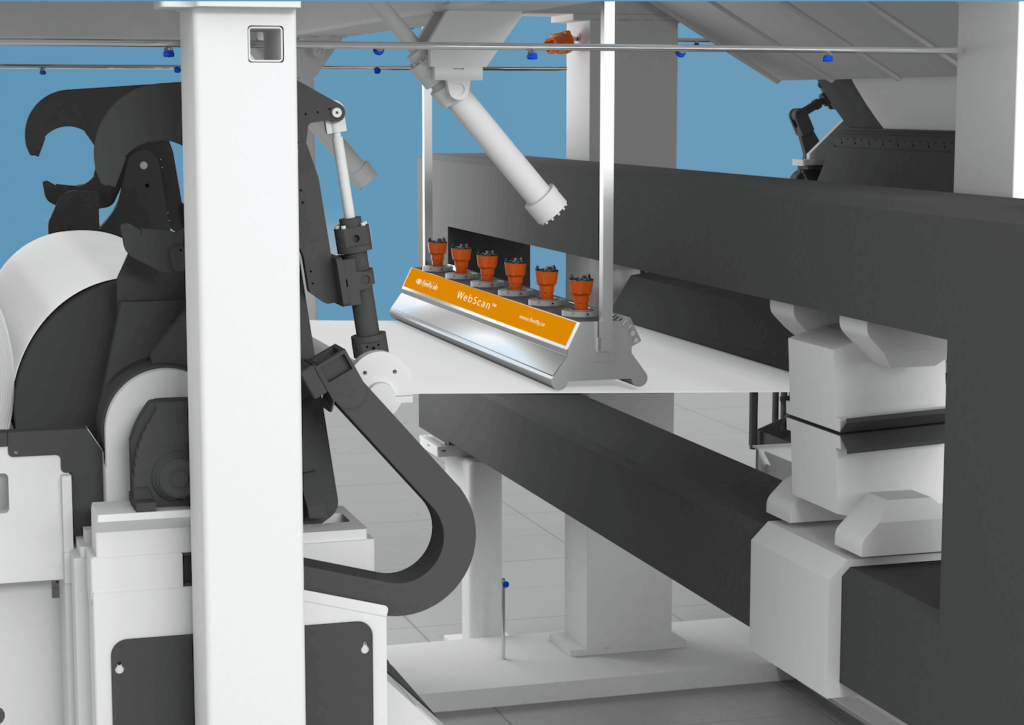

Firefly introduces the WebScan™ solution. Firefly WSD detectors are specially designed for fire prevention in this process. They identify sparks or overheated particles on the paper sheet and notify the operator in case of a potential risk.

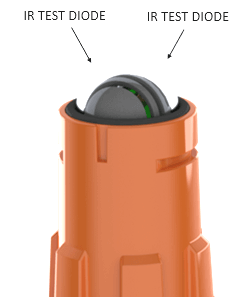

WSD detectors are equipped with patented True IR technology, these detectors work on the infrared range, therefore could detect energy and temperature levels below the Minimum Ignition Temperature (MIT), in this case 270ºC (Cellulose) and Minimum Ignition Energy (MIE), 0.080J, according to the NFPA Explosion Characteristics of Various Dusts.

It is also worth mentioning, that no body emits light until it reaches above 650ºC, this means that a conventional spark detector would not be able to detect a particle below this temperature, because they are based on the use of silicone cells that only react to light.