Fire protection in the power generation industry

Generate power without risk of fire

Power generation facilities face numerous fire and explosion risks, demanding vigilant safety measures. Common hazards include hot particles and foreign objects, like stones and metal, within incoming materials, posing ignition risks. Friction from material build-up at various process points also heightens the threat.

Optimize your power generation processes for safety and efficiency. Our comprehensive solutions mitigate fire risks, ensuring uninterrupted power production while safeguarding against potential disasters.

100

degrees C – normal running temperature for steam turbine generator bearings

26

million dollars – average property loss for turbine building fire

Mitigating fire risks associated with turbine lubrication oil

Turbine lubrication oil presents a significant fire hazard, particularly as turbine operating temperatures can surpass the oil’s ignition point. Additionally, conveyors pose risks, as objects like stones and metal fragments in incoming materials can impede flow, leading to temperature spikes. Friction from material accumulation further exacerbates these dangers.

Consider the scale: Large steam turbine generators require thousands of litres of oil for bearing lubrication. In the event of oil leakage, triggered by factors like vibrations, operator oversight, or electrical faults, the ensuing fire can result in catastrophic consequences for the entire plant.

Ensure your facility’s safety by implementing robust measures to mitigate these risks effectively.

Countering high costs and downtime caused by fires

Research conducted by FM Global reveals that inadequate fire protection was a significant factor in 17 major turbine building fires studied. The resulting property damage, excluding lost production, exceeded $400 million, with an average property loss of $26 million per incident. These fires led to turbine downtime ranging from 10 days to 48 weeks, resulting in a loss of generating capacity surpassing 20 million MWh.

Firefly offers proactive protection for your power generation facility. Our advanced systems detect and extinguish hot particles within your processes, anticipating potential fires and ensuring uninterrupted operations. Safeguard your facility with Firefly to maintain operational continuity and minimize risks.

Custom solutions for the power generation industry

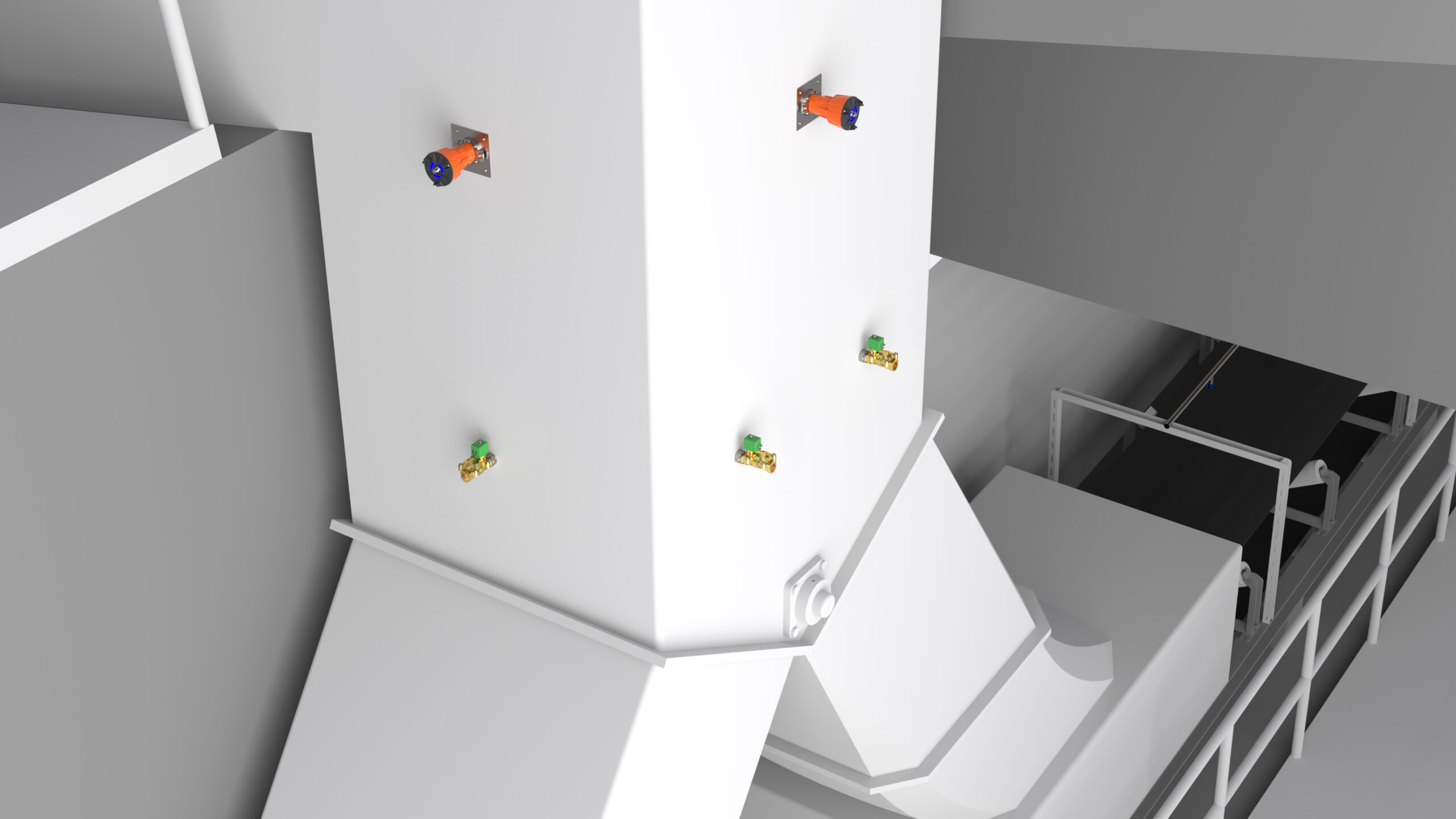

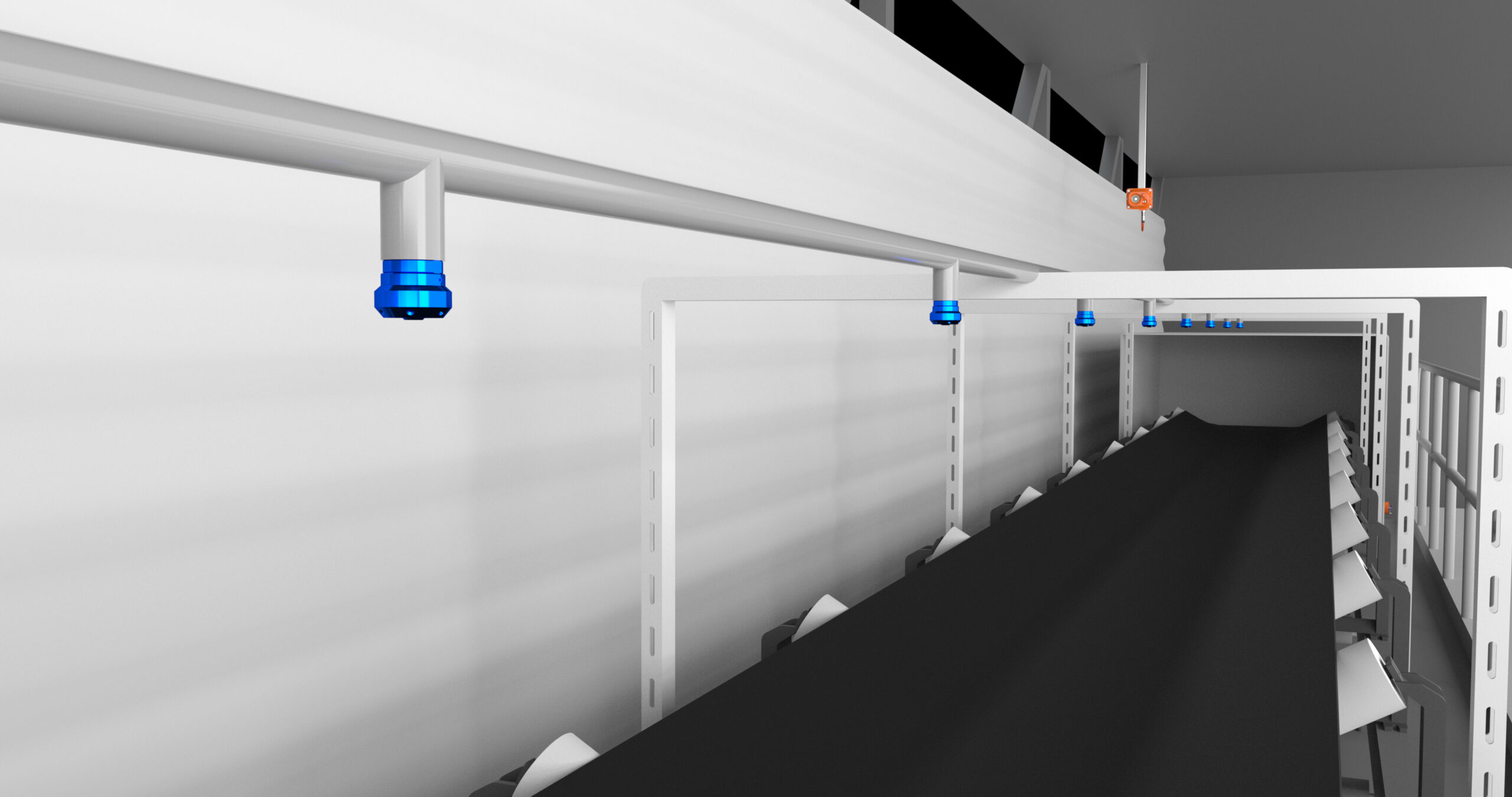

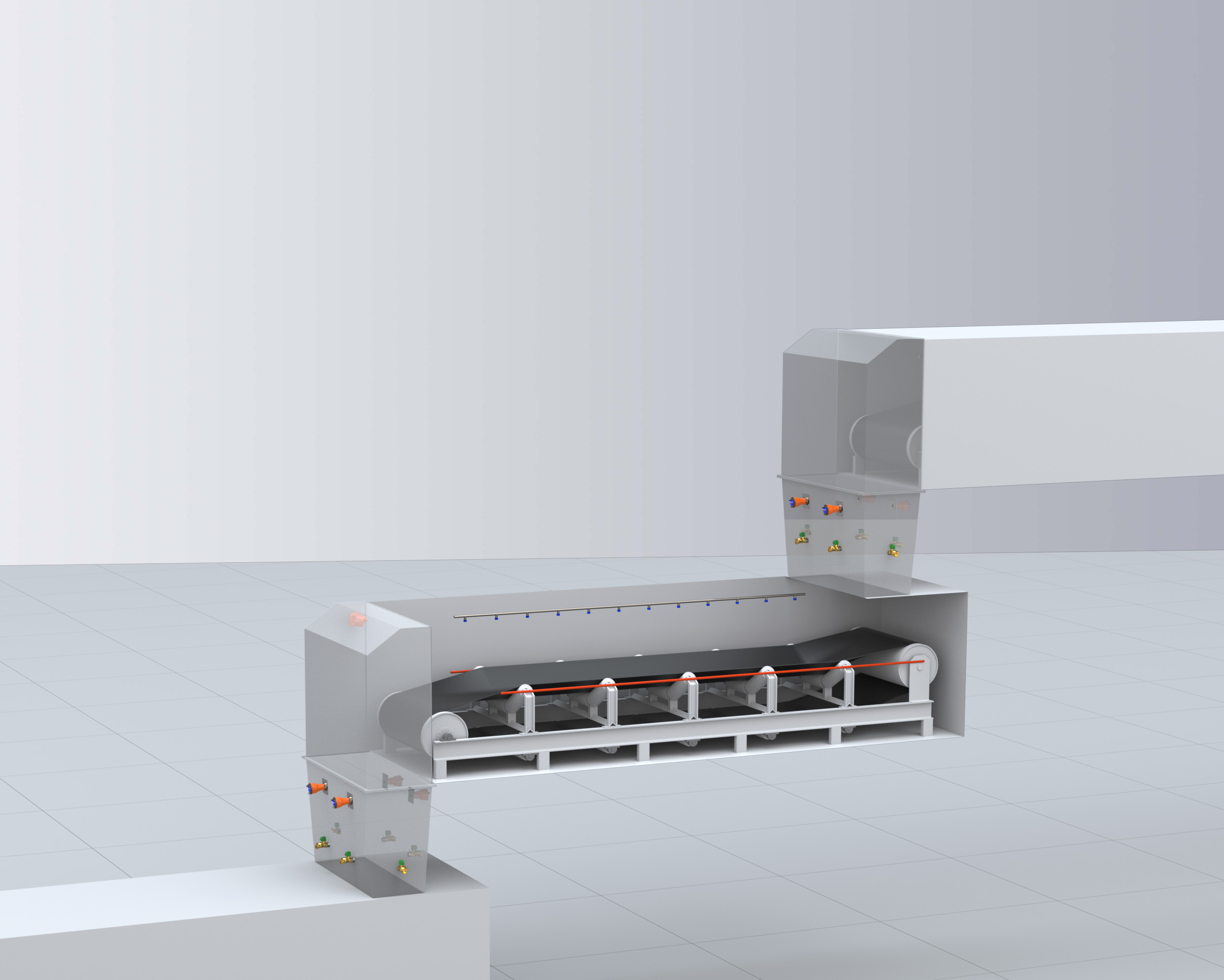

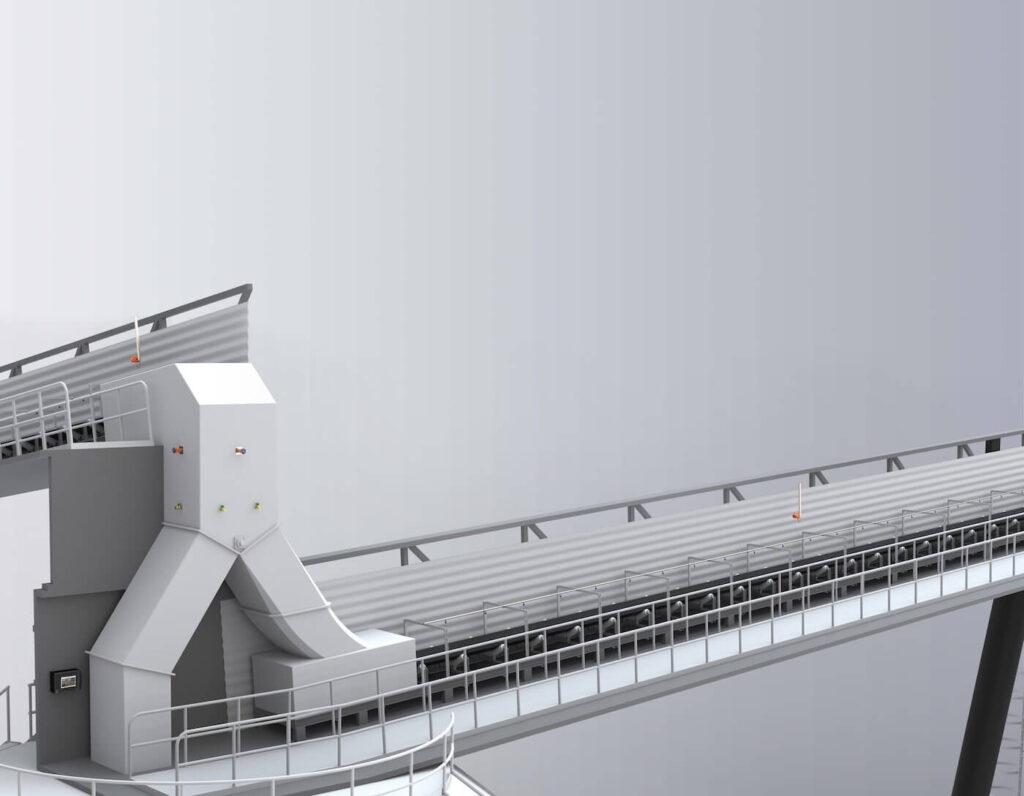

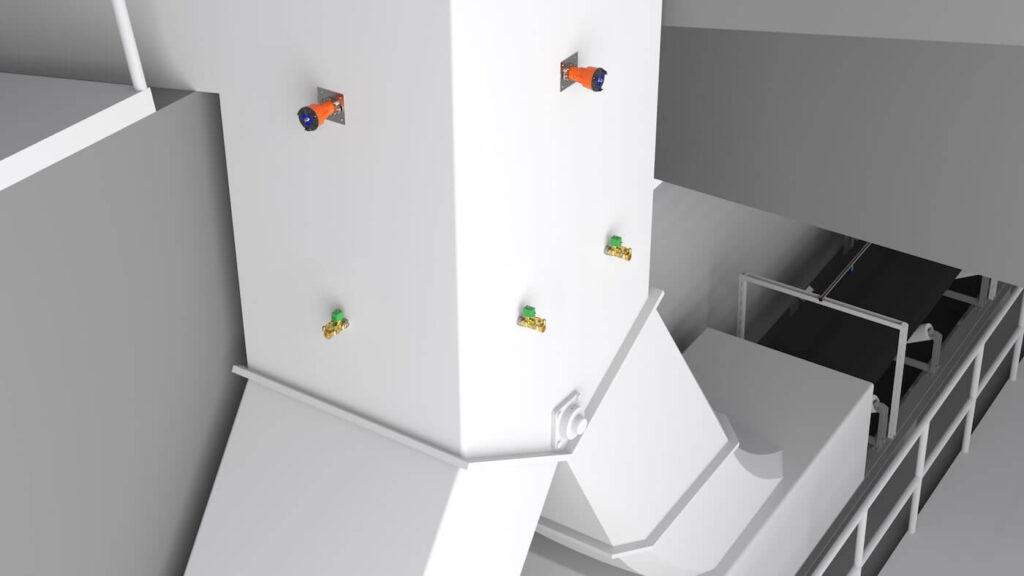

Firefly ConveyorGuard™

A fire in a belt conveyor is often hard to extinguish and can spread very quickly. In the worst case it can spread to surrounding material stacks and could last for weeks, causing major loss of revenue and production downtime.

The purpose of the Firefly ConveyorGuard™ solution is to automatically detect and suppress a fire at an early stage and to stop the conveyor belt as quickly as possible. The Firefly ConveyorGuard™ solution can be complemented with Firefly open area flame detectors and/or LTS cable.

Key benefits

Quick System Response Time

Minimum Water Usage

Third Party Approved System

Precision Detection

Safe and certified for your industry. Read more about our certifications and approvals here.

Unique Fire Protection Solutions for the recycling industry

ULTRA QUICK SYSTEM RESPONSE TIME

The Quick Suppression System, which is part of our protection solution for shredders, operates with high performance flame detectors for extremely quick detection. The efficient water mist system has remarkable suppression capabilities which reduce damages on machinery.

PRECISION DETECTION

The True IR Spark detectors enable Precision Detection of ALL types of ignition sources such as hot black particles, glowing embers and sparks. The detectors are insensitive to daylight. Systems are also equipped with Multi-Channel flame detectors, using advanced algorithms for Precision Detection of flames with high immunity to false positives.

EXCELLENT SUPPRESSION CAPABILITIES

The Water Mist System with fire-tested and verified extinguishing capabilities utilizes very small amounts of water resulting in less impact on machinery, minimized production loss and down time.

FULL-CONE WATER SPRAY EXTINGUISHING

Powerful extinguishing with a unique nozzle design and placement aimed to penetrate and cover the entire material flow. Activated within milliseconds after detection.

Downloads

Firefly ConveyorGuard™

Firefly EXIMIO™

Firefly Spark Detection System

Firefly Quick Suppression System

Keeping industry leaders safe