Fire protection for the tissue industry

Reducing fire hazards for continuous operations

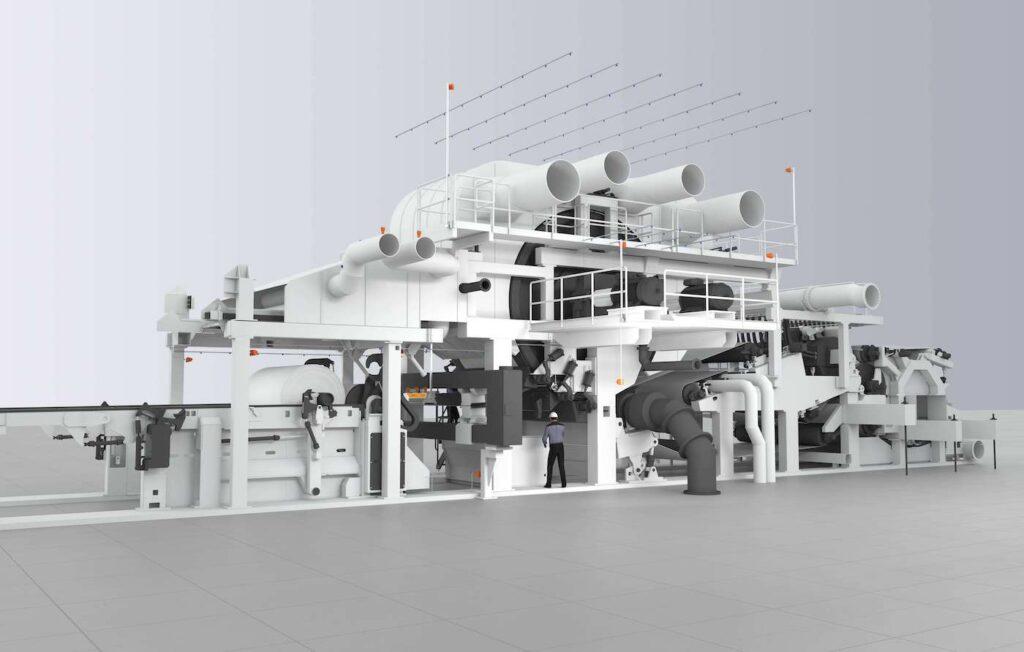

Fire hazards in the tissue manufacturing industry can jeopardize operations, endanger personnel, and threaten assets. Understanding and managing these risks are crucial for ensuring continuous production and averting potential disasters.

Discover how to reduce common fire hazards, control combustible material buildup, and implement preventive measures to safeguard your facility, personnel, and assets from fire incidents.

500

degrees C – running condition of a medium temperature yankee hood

1250

degrees C – running condition of a very high temperature yankee hood

Identifying fire hazards in tissue manufacturing

Dry, flammable materials abundant in tissue manufacturing lines create a conducive environment for fire incidents. From cellulose dust and fibres to combustible material buildup, various factors contribute to the heightened risk of fires.

Equipment failures, including those resulting in elevated temperatures, pose additional fire hazards and can lead to process disruptions and potential plant-wide losses if fires spread to warehouses or storage areas.

Managing combustible material buildup

Tissue manufacturing’s high-speed operations exacerbate the accumulation of combustible materials, increasing the risk of fire incidents. Margins are narrow, making any disruption to the process financially impactful.

Implementing effective management strategies, such as regular cleaning and maintenance routines, helps mitigate the risk of combustible material buildup and minimizes the potential for fire outbreaks.

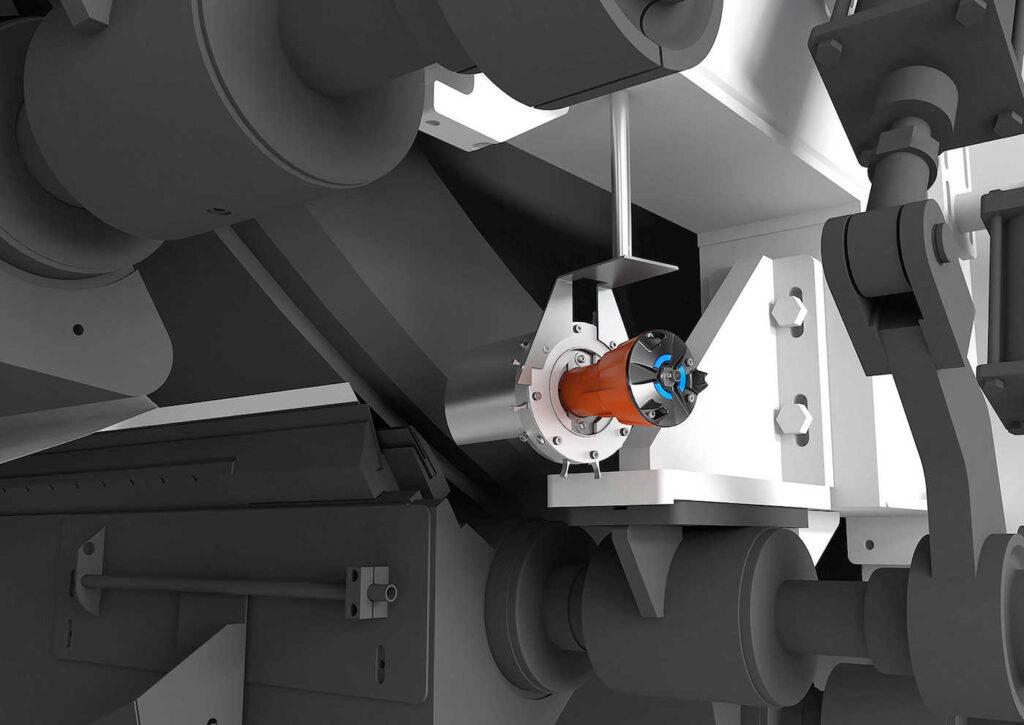

Preventing Hot Particle Incidents

Hot particles, particularly those originating from production-related processes like the yankee hood dryer, present a significant fire risk. These particles can become embedded in tissue reels and pose a threat when transferred to storage areas.

Utilizing advanced detection systems and preventive measures, such as spark detection and suppression systems, helps identify and mitigate hot particle incidents, reducing the likelihood of major fires in tissue manufacturing facilities.

Custom solutions for the tissue industry

Firefly Tissue Solutions®

Firefly provides comprehensive solutions designed to prevent and protect against fires in these high-risk areas, ensuring the safety and continuity of operations. Our solutions provide detection of sparks and suppression of flames within seconds, using a combination of the Spark Detection and Quick Suppression System with optical flame detectors that detect small flames at an early stage, over a large area, combined with water mist suppression.

Key High-Risk Areas Include:

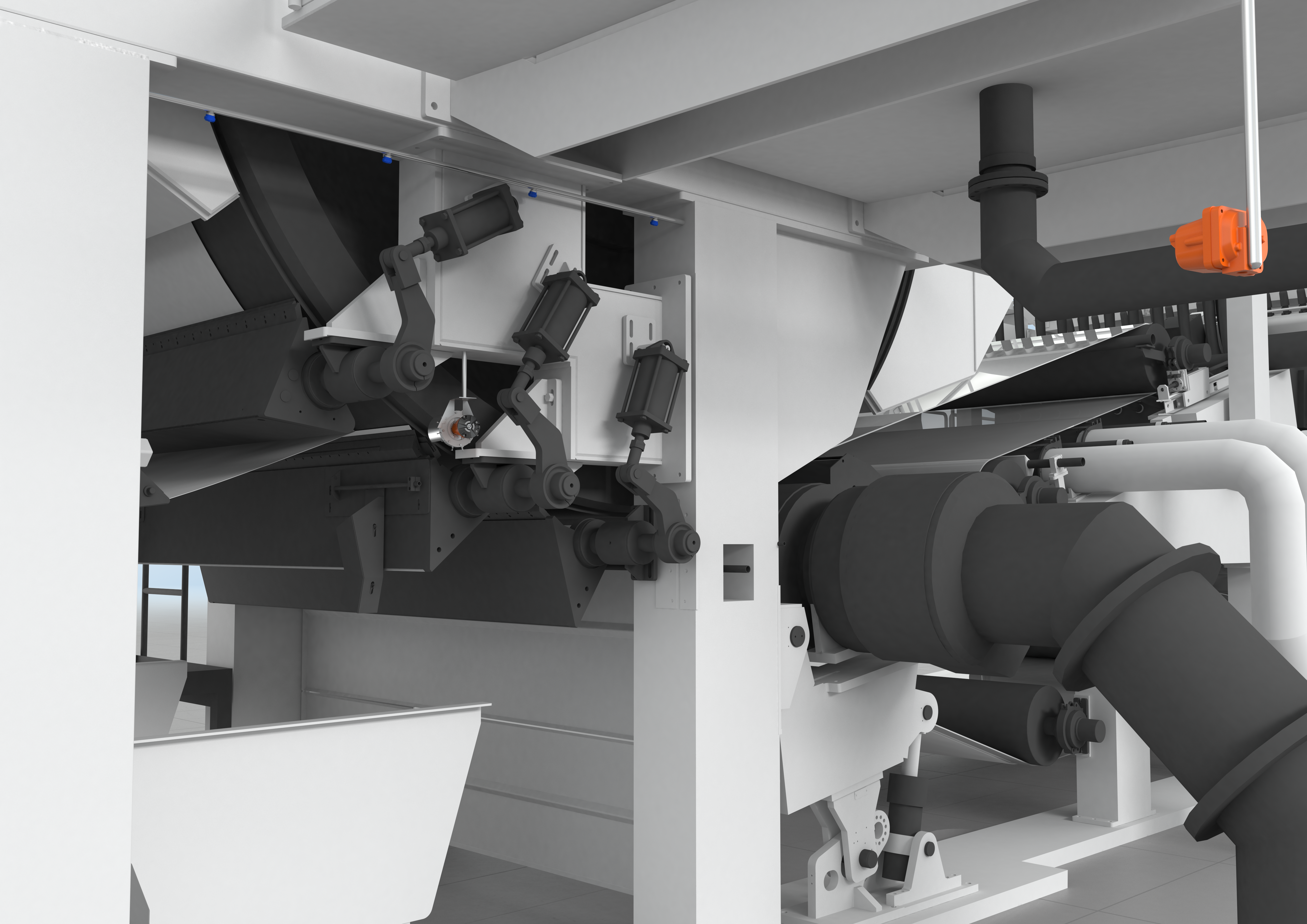

- Top of Yankee Hood & Ducts Protection

- Yankee Drive Side Protection

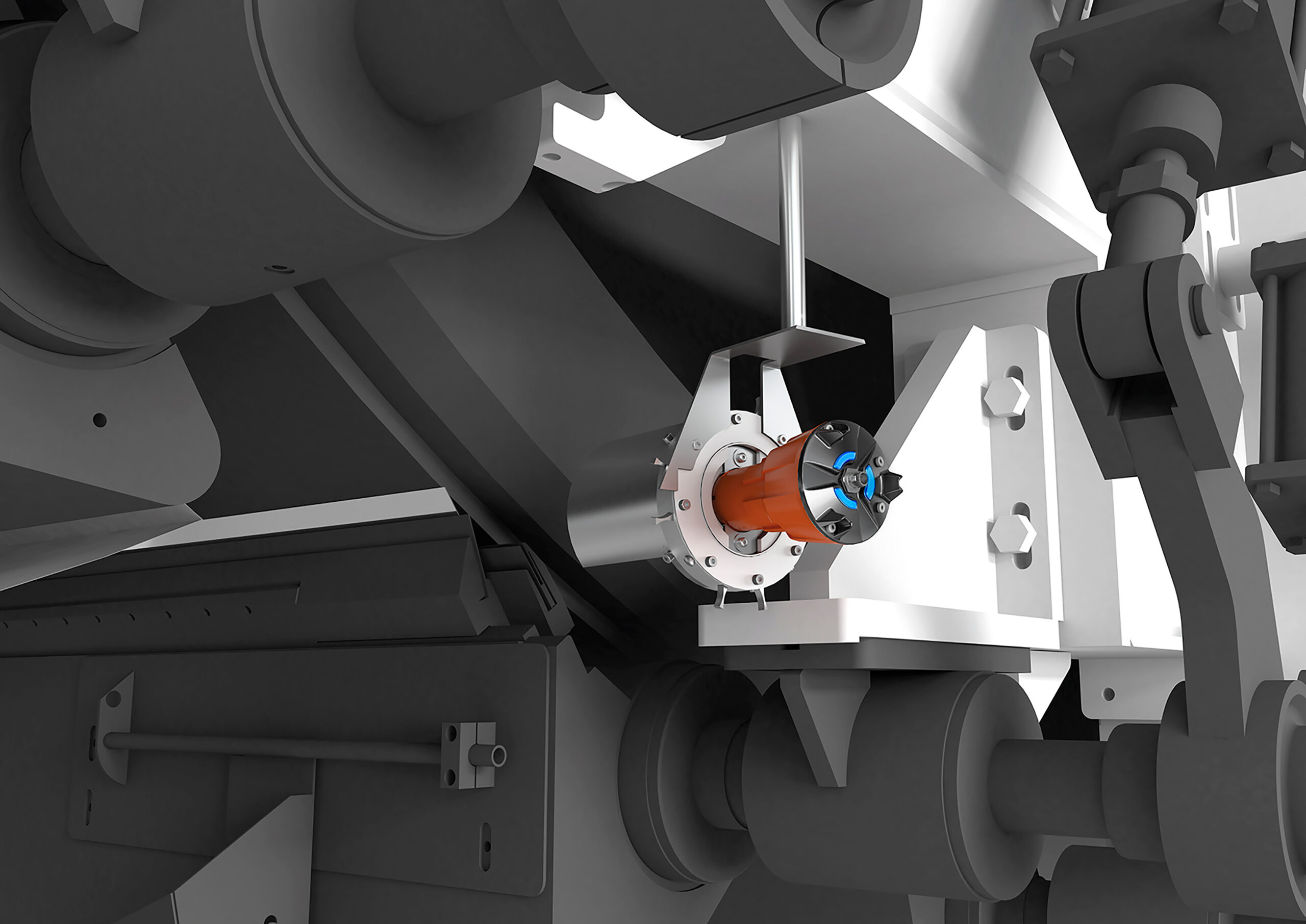

- Doctor Blade Area Protection

- Doctor Blades – Spark Alert

- WebScanTM

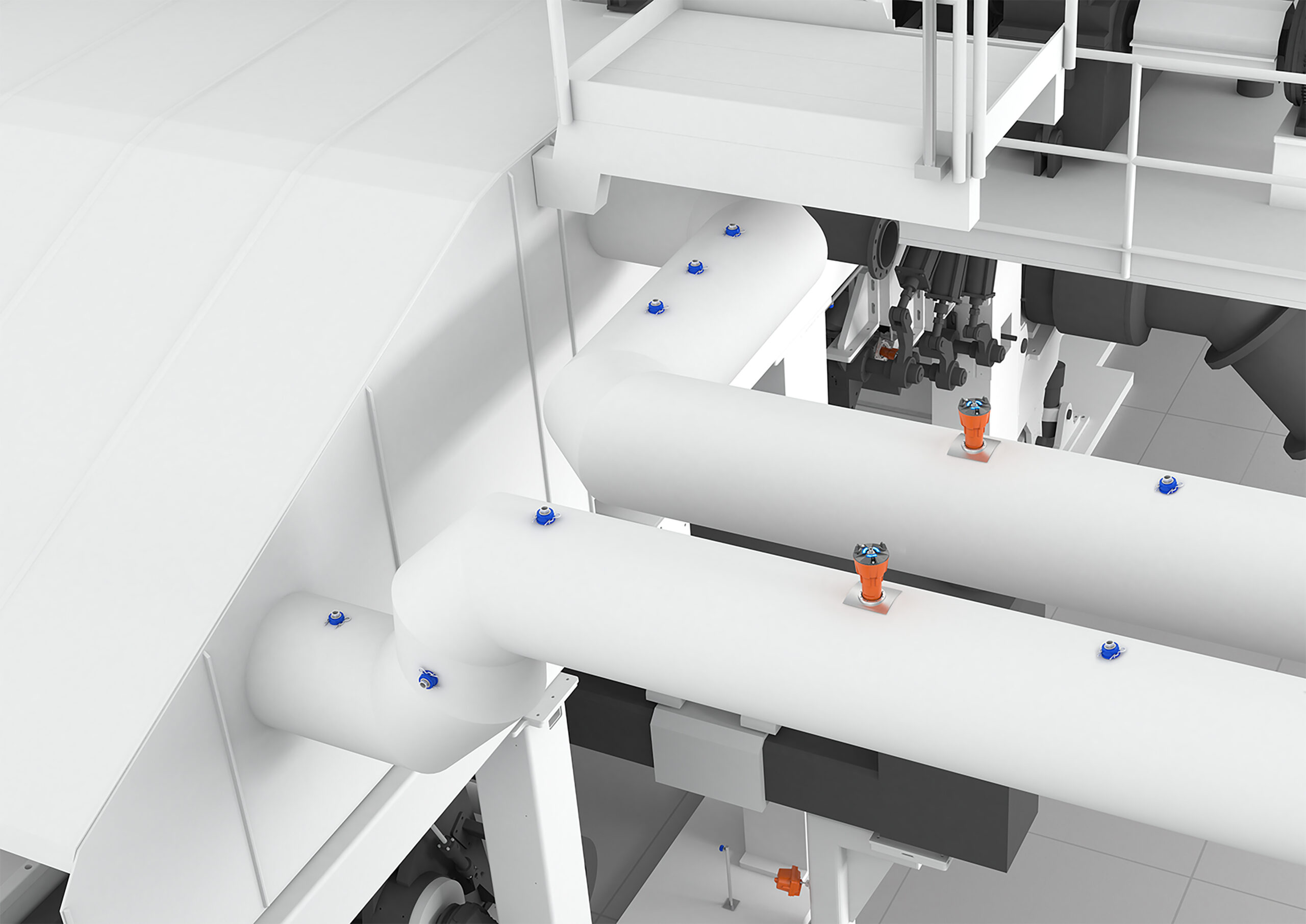

- Dust Extraction Protection

- Dry-end of Machine Protection

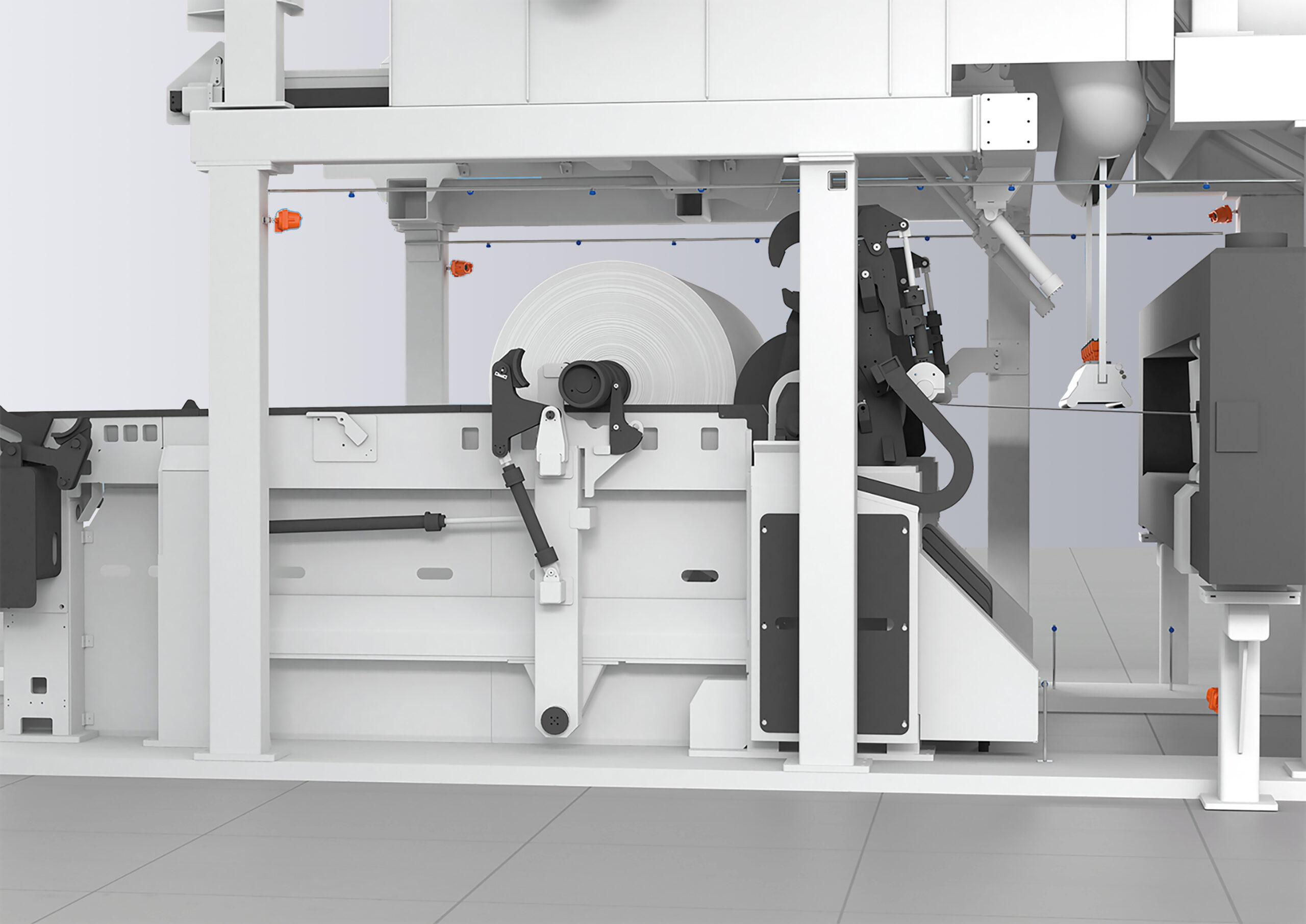

- Reel-up Area Protection

- Storage Area Protection

Our diverse range of solutions is tailored to address specific fire risks in each area, offering proactive prevention measures and robust protection mechanisms. Trust Firefly to safeguard your facility against potential fire hazards, minimizing risks and ensuring operational resilience.

Enhancing Storage Area Protection

In tissue storage areas, fires can escalate rapidly, often originating from subtle smoldering around parent rolls, challenging traditional detection methods like smoke detectors. To address this critical issue, Firefly offers an integrated solution combining two cutting-edge technologies, prioritizing both personnel safety and operational continuity.

Firefly Multi Gas Detector

Our Multi Gas Detector (MGD) functions as an “electronic nose,” providing early warnings by identifying gas trends indicative of potential fire hazards in the storage area. Equipped with advanced electrochemical sensors, the MGD accurately analyzes various gas combinations, enabling prompt detection of incipient combustion processes. Upon detection, visual and audible alarms alert personnel, ensuring swift intervention to mitigate risks.

Firefly Open Area Flame Detector

Our state-of-the-art flame detectors offer comprehensive coverage of risk zones within storage areas, boasting superior flame identification capabilities with minimal false positives. Designed to withstand harsh and dusty environments, these detectors are ideal for larger storage facilities. Firefly customizes each system to optimize detector placement, ensuring maximum effectiveness based on the storage area layout.

Key benefits

Avoid production stops due to fires

Minimum Water Usage

All Firefly detectors are insensitive to daylight

Robust systems with certified technology

Safe and certified for your industry. Read more about our certifications and approvals here.

Unique Fire Protection Solutions for the tissue industry

ULTRA QUICK SYSTEM RESPONSE TIME

The Quick Suppression System, in our protection solutions for Tissue, operates with high performance flame detectors for extremely quick detection. The efficient water mist system has remarkable suppression capabilities which reduce damages on machinery.

EXCELLENT SUPRESSION CAPABILITIES

The Water Mist System with fire-tested and verified extinguishing capabilities utilizes very small amounts of water resulting in less impact on machinery, minimized production loss and down time.

FIREFLY WEBSCAN™ SYSTEM

This is a unique concept that detects dangerous ignition sources such as hot dark particles, glowing embers or sparks on the tissue web and alarms the operators to avoid fire in the mother rolls.

SPARK ALERT – DOCTOR BLADESHEADING

Friction created by the Doctor blades in combination with accumulation of dust can cause fires that can spread rapidly. If any dangerous ignition sources are detected, such as hot black particles, glowing embers or sparks, then an alarm signal is given by the control unit. This will not activate the water mist, just alert the operators.

Downloads

Firefly Tissue Solutions®

Firefly Tissue Converting

Firefly Quick Supression System

Firefly MGD

Firefly EXIMIO™

Firefly Spark Detection System

Keeping industry leaders safe