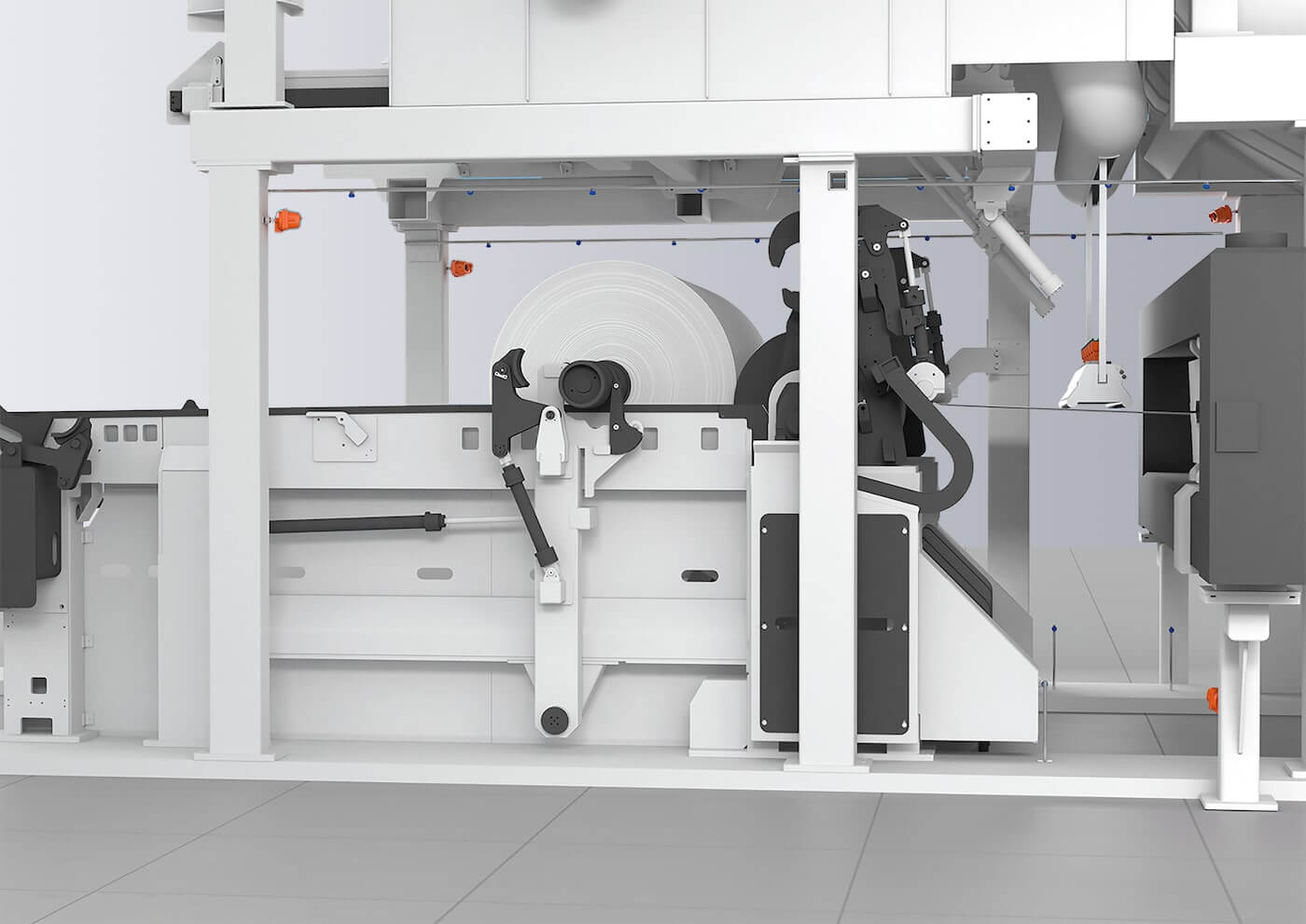

The same paper encapsulates the overheated particles, and once the fire begins to spread through the roll it doesn´t generate smoke, so traditional equipment will not be able to identify the fire before it is too late.

Every year numerous fires occur in jumbo roll storage around the world, generating millions and millions of euros in losses. In response to this problem, Firefly ab has conducted a series of tests with various manufacturers of tissue paper to determine the fire risks during the production and storage of a jumbo roll.

The tests were performed considering those jumbo rolls in which the Firefly WebScan™ detected overheated particles. These overheated particles were a product of dust that came off the yankee hood and fell on the sheet, plus sparks that were generated in the creping blade area.

These rolls were taken to an isolated area where additional equipment was installed to investigate the evolution of the overheated particles inside them.

The first thing that was noticed when investigating the rolls is that the paper itself encapsulates the overheated particle, which means that this particle can generate a fire in any direction within the roll. The fire or ember tends to move faster laterally than radially. Also, from the results of the investigation it was determined that the expansion speed decreases as the surface of the roll approaches. This characteristic is due to the cooling capacity that is greater on the surface of the jumbo roll.

Regarding the energy required to start a fire inside a jumbo roll, it was observed that, in papers with a less dense structure, the energy required is also lower; while in papers with a denser structure, more energy is required. Those papers which have a “higher” content of air within their structure are more prone to develop a fire.

Continuing with the investigation, it was deduced that once the fire starts to spread through the jumbo roll, no smoke is generated, a characteristic that increases the danger of these events.

The smoke was generated just as the fire was about to reach the surface of the roll.

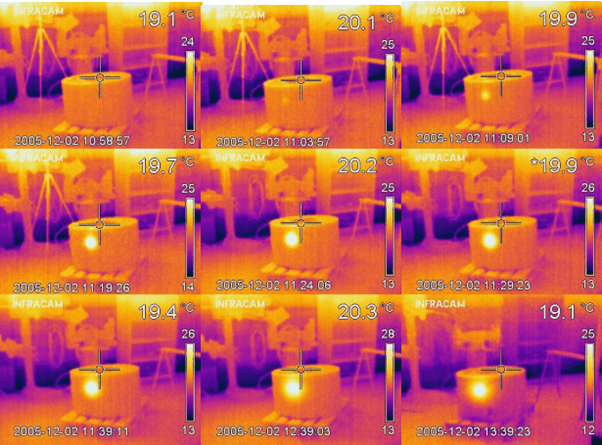

Infrared cameras were also used during the test, both to support the research and to test them as an alternative detection method. And it could be noted that they are a good help if they are in the vicinity of the roll and the fire is on the surface. However, if the fire is inside the roll, the IR camera will not be able to detect the fire, given the insulating properties of the tissue paper, which absorbs radiation. By the time it identifies it, the fire will already be on the surface and it will be too late to act.

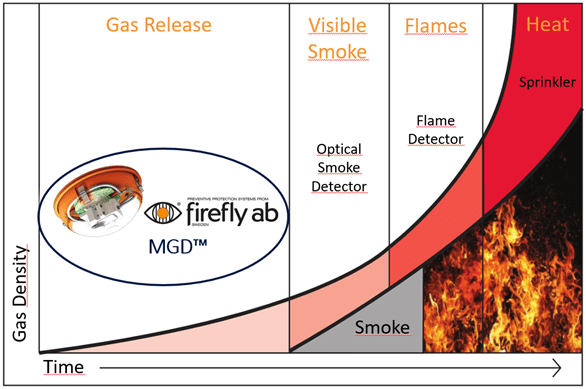

At this point, with no smoke or flame, the only possible way to detect this fire is by analyzing the chemical components present in the air.

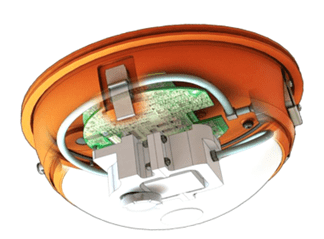

In response to this, Firefly offers a next generation solution for jumbo roll storage protection, the MGD™ detector, or “Electronic Nose”.

The MGD was designed to use pattern classification with a neural network, mimicking our nose. It makes an intelligent analysis of the chemical composition of the environment and the different combinations of gases, this means that it “smells” the environment in which it is installed, and looks for the different patterns of substances in the air that indicate the beginning of a combustion process. To give an example, it is as if one of our neighbors is doing a barbecue, we cannot see it but just by the smell we know that he is cooking meat.

This also means that Firefly’s multiple gas detector is capable to give an early warning that something is happening in the storage since it doesn´t need to wait for the smoke or the flames that come on a later part of the fire evolution. This detector works in the first part of a fire’s evolution, when the gas release is just starting.

The “smell” generated from the combustion of each type of material creates a unique pattern, so that a classification of materials is possible. Thus the “harmless” combustion gases that are normally present in the environment can be ignored.