In industrial environments, fire risk is a constant challenge that requires both knowledge and technology to prevent accidents. By understanding concepts such as ignition temperature and flash point, companies can better manage these risks. Firefly offers innovative solutions to detect and prevent hot particles and flames before they can spread. Let’s dive into what these terms mean and how Firefly can help keep your workplace safe.

What is ignition temperature?

Ignition temperature is a crucial measurement in industry. It’s the lowest temperature at which a material can start burning on its own without an external ignition source, like a spark or open flame. When the temperature reaches this critical level, the material starts to emit gases that can react with the oxygen in the air and lead to spontaneous combustion.

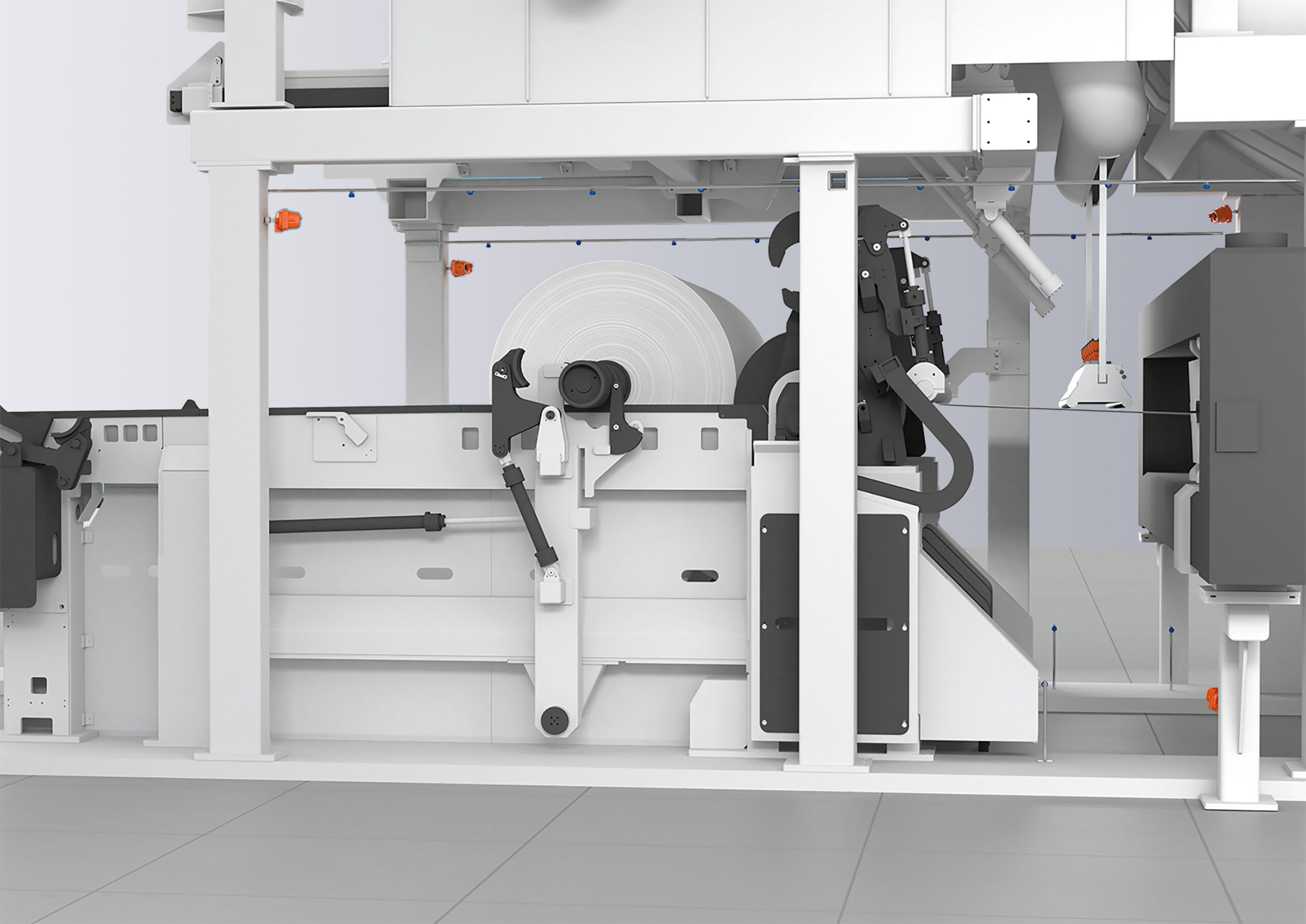

In practice, this means that if you have materials stored or processed near hot surfaces or during processes that generate heat, the risk of fire can quickly increase. To prevent this, Firefly offers advanced spark detection systems that can identify and extinguish sparks before they develop into dangerous fires.

Flashpoint vs. Ignition Temperature – An Important Difference

In fire safety, it is important to distinguish between ignition temperature and flash point. Flash point is the temperature at which a liquid begins to give off enough steam to ignite, but an external source, such as a spark, is still required for a fire to start. The ignition temperature, on the other hand, is the temperature at which the material self-ignites without any external influence.

This distinction is not just theoretical. For companies handling both solids and liquids, it is a practical matter of safety. With Firefly’s combination of spark detection and rapid extinguishing systems, even the smallest ignition sources can be detected and eliminated immediately.

How flammable is wood?

Wood, one of the most widely used materials in industry, is also one of the most flammable. The ignition temperature of wood ranges between 300°C and 400°C, depending on the species and moisture content. When you process wood, whether it’s by sawing, sanding or other mechanical processing, sparks are generated that can quickly ignite dust and chips.

Firefly’s spark detection system can quickly identify sparks and extinguish them with water mist before they can cause damage.

Paper – A hidden danger

Paper has an even lower ignition temperature, between 218°C and 246°C. In environments such as printing plants, packaging factories or recycling facilities where paper is handled in large volumes, a single spark can lead to a fast and uncontrollable fire. Firefly systems are designed to detect and eliminate sparks or small fires at an early stage, reducing the risk of lengthy and costly production downtime.

Other materials to watch out for

In addition to wood and paper, there are several other materials handled in industry that also pose a fire risk:

– Aluminum: With an ignition temperature of around 650°C, aluminum is not as flammable as wood, but finely divided aluminum chips can ignite at lower temperatures. Firefly’s spark detection is an important insurance against such unexpected ignitions.

– Polyethylene (PE): Polyethylene is a plastic that ignites at around 349°C. It burns with a very hot flame and can quickly spread fire throughout a facility. Firefly’s system can be used to continuously monitor temperatures and extinguish any fire sources before they cause major problems.

– Oil and grease: With ignition temperatures between 300°C and 400°C, oils and greases are common in many industries. If spilled near hot machinery, they can quickly ignite. This is where Firefly’s flame detection systems can be vital, as they immediately detect, react and extinguish.

Temperature classes – Understanding and using them correctly

Industrial equipment is often categorized into temperature classes depending on the highest surface temperature they can reach during normal operation. This is important to prevent the equipment from becoming a source of ignition for nearby materials.

- T1: Up to 450°C

- T2: Up to 300°C

- T3: Up to 200°C

- T4: Up to 135°C

- T5: Up to 100°C

- T6: Up to 85°C

Integrating Firefly’s systems into your facilities means you can keep these temperatures under control, reducing the risk of equipment causing fires.

Innovative technology for fire prevention

At a time when industry is facing increasing demands for safety and efficiency, understanding ignition temperatures and implementing advanced fire prevention systems plays a crucial role.

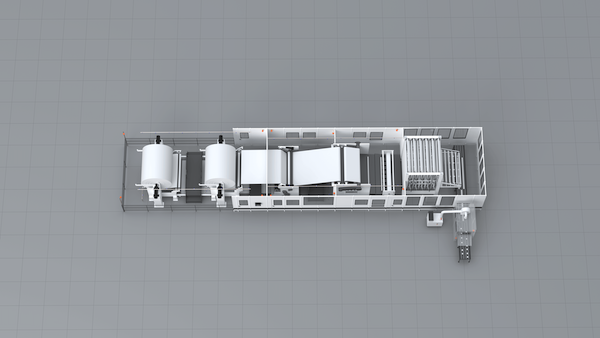

Firefly’s solutions range from spark detection to advanced flame detection systems and rapid extinguishing systems, adapted for different types of industries. The technology is particularly effective in high fire risk environments, such as the wood and paper industries, and has proven to be crucial in preventing disasters.

By integrating Firefly’s systems into your workplace, you not only gain increased safety but also a head start in responding to potential fire risks before they become dangerous. It’s an investment in both safety and sustainability.