Fire protection of port facilities and logistical terminals

Securing port operations

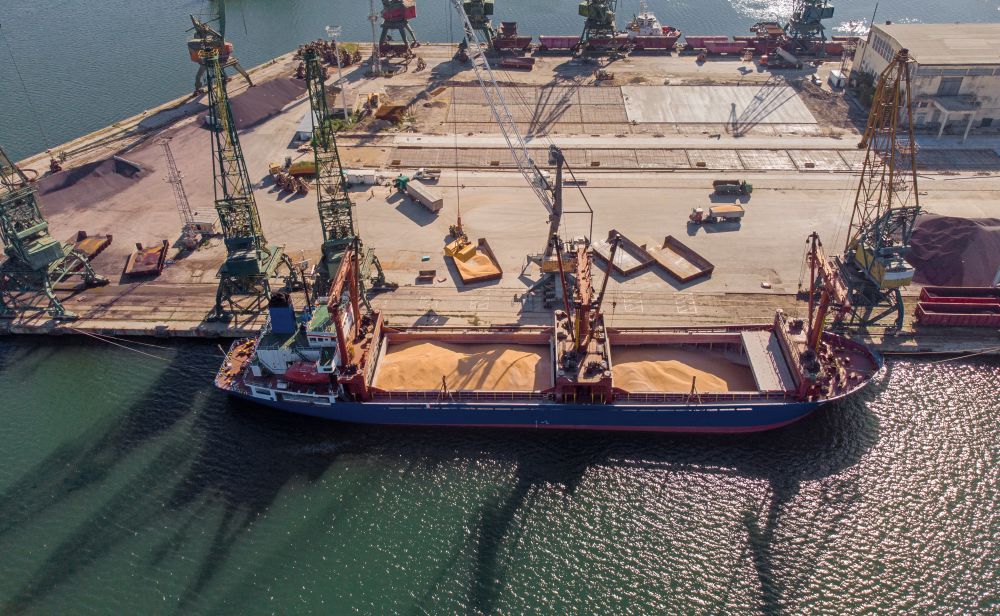

Fires in port facilities can result in severe consequences, with some areas being challenging to reach and containing a fire proving difficult once it starts. Given the 24/7 nature of port operations, fires can lead to extensive costs, disrupt supply chains, damage equipment, and pose unacceptable risks to workers’ safety. Our priority is to implement robust safety measures to prevent and address fire hazards, ensuring uninterrupted port operations and safeguarding personnel and assets.

90%

of yard equipment fire is caused by hydraulic leakage

500

degrees C is the ignition temperature of hydraulic oil spray

High risk in port facilities and logistical terminals

Port facilities and logistical terminals present multiple high-risk areas prone to fires or dust explosions.

Stored materials at ports pose potential fire hazards, especially when the contents of containers are unknown. Proper storage of containers containing flammable substances like alcohol or fuel is essential. Additionally, loose materials such as wood chips can self-combust under specific conditions, generating flammable dust during handling. The continuous movement of vehicles further exacerbates the fire risk, with hot engine parts and exhaust systems, along with potential fuel and oil leaks.

Implementing comprehensive fire safety measures is crucial to safeguarding port facilities and logistics terminals from potential fire incidents and ensuring the protection of personnel and assets.

Dangerous scenarios in the process:

- Friction heat generation (i.e. stalled roller)

- Mechanical failure (i.e. bearing)

- Material build-up/dust accumulations

- Impurities in the processed material

- Limited access for maintenance or manual extinguishing

- Self-ignition

Hydraulic oil – a fire hazard

90% of yard equipment fire is caused by hydraulic leakage, with pressurized hydraulic oil presenting a considerable fire hazard. If the system is damaged and oil is released, the resulting spray can reach as far as 10 metres away. The ignition temperature of hydraulic oil is 500 to 530 degrees, so in the presence of hot surfaces and ignition sources, this can cause a fire with considerable consequences.

The increasing use of electric vehicles with ion-lithium batteries in port operations adds yet another dimension, with the potential to cause a battery fire due to runaway chemical reaction.

In addition, mechanical failure and foreign objects in the material flow inside handling machinery can cause friction and elevated temperatures, leading to a fire.

Securing ports – innovative fire safety solutions

Firefly offers a range of solutions for spark detection and quick suppression, protecting loading and unloading areas, conveyors, chutes, elevators, filters and silos.

The large quantities of bulk material being processed creates spillage and fine dust, which can easily spread and accumulate in different parts of the equipment. The root cause of a fire in this type of process can be, for instance, mechanical failures such as stalled rollers or bearing failure, or impurities in the material entering a mill.

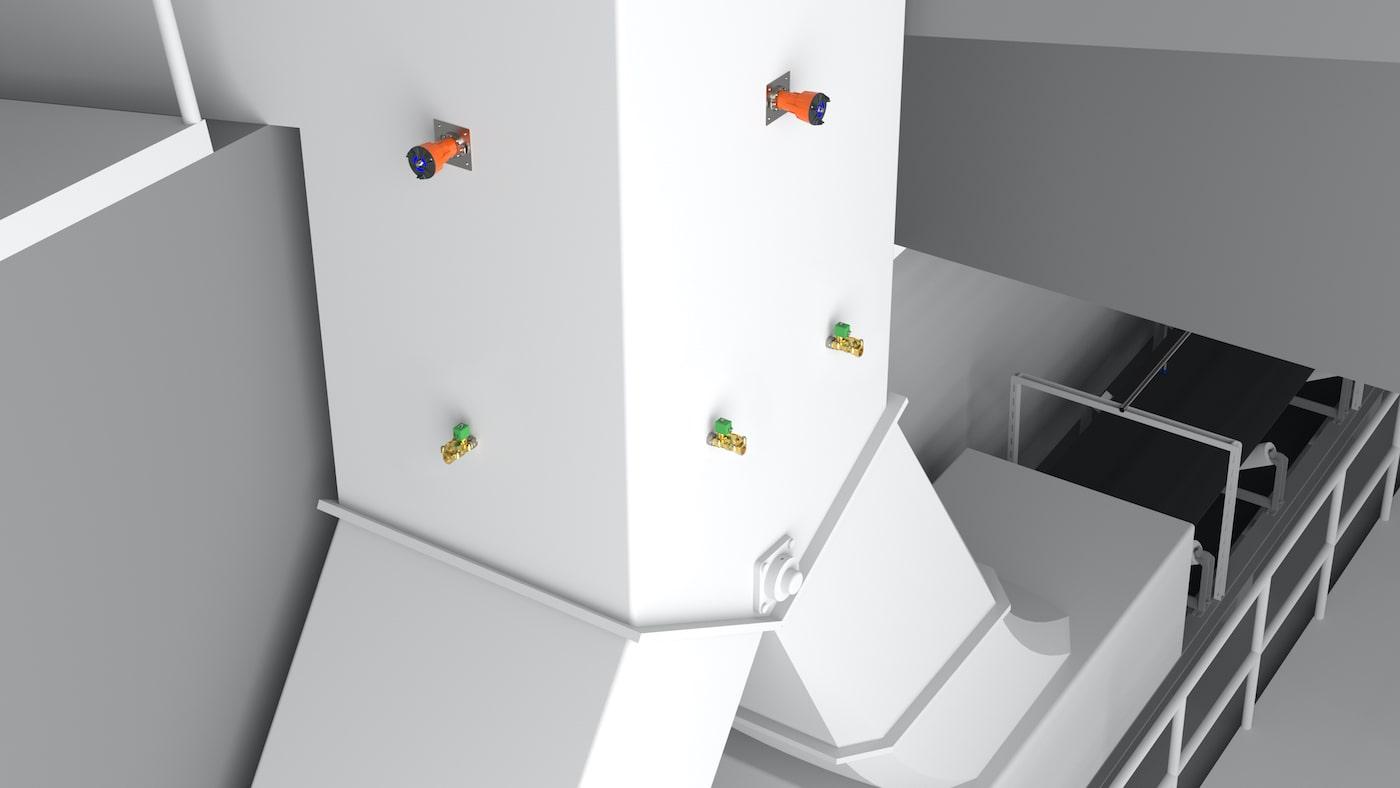

Movement of materials containing hot particles poses particular challenges in port operations. These ignition sources can easily be transported through the duct systems and cause fires or explosions further down the process, for example in chutes, conveyors, silos or dust collection systems.

In the event of a fire, it can spread fast and have devastating consequences due to the difficulties in reaching the affected areas, which is often the case with conveyor belts and elevators high above ground.

Firefly provides a wide range of equipment for effective fire prevention and suppression i port areas, protecting open areas as well as material streams enclosed inside ducts and machinery.

.

Custom solutions for the port industry

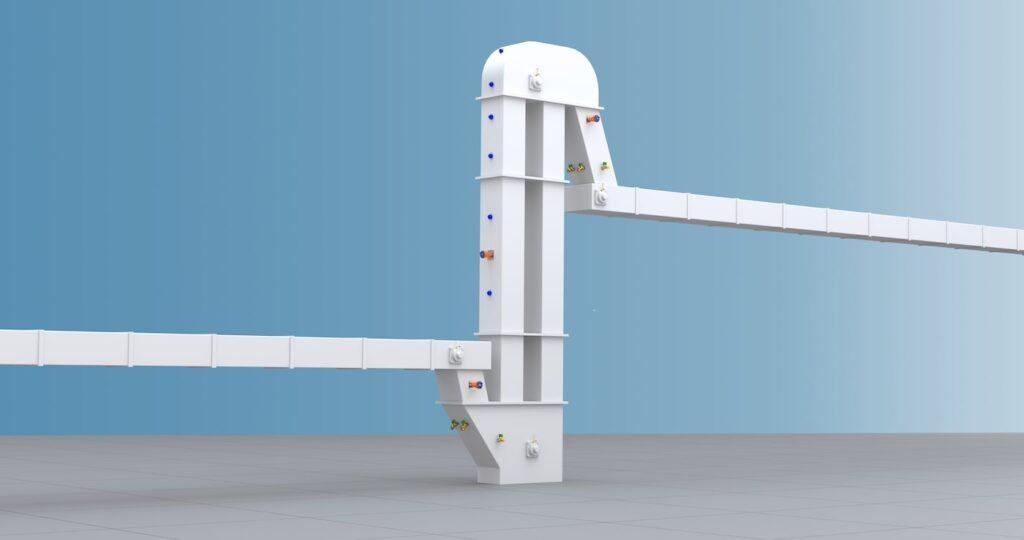

Firefly ElevatorGuard™

The dusty atmosphere inside an elevator is ideal for a fire or a dust explosion. The properties of a bucket elevator also makes it more complicated to protect. A fire can start due to ignition sources being fed into the elevator, but ignition sources can also be generated inside the elevator itself.

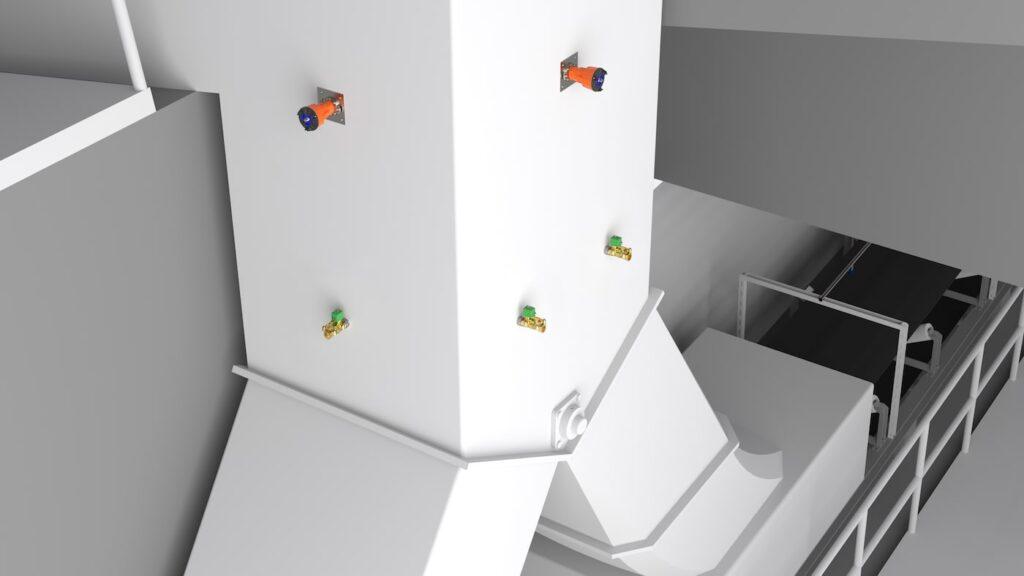

The Firefly ElevatorGuard™-solution includes FM-approved, True- IR hot particle detectors and full cone water extinguishing nozzles at the inlet and outlet of the elevator. At the inlet, the Firefly system will minimize the risk of any dangerous ignition sources to enter the elevator. If the root cause is inside the elevator, the system at the outlet will give an early indication of a beginning problem inside the elevator and minimize the risk of ignition sources leaving the elevator to downstream process parts.

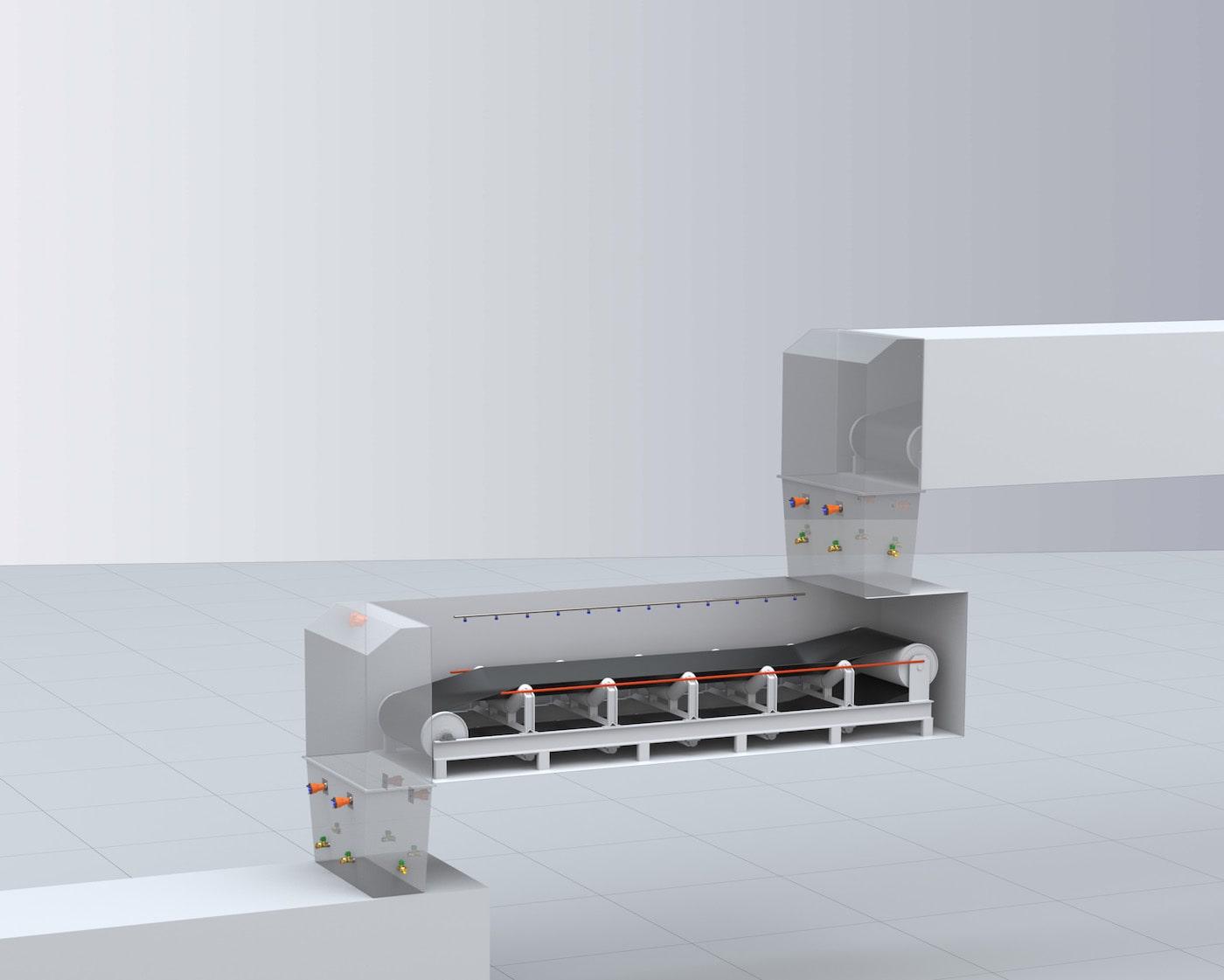

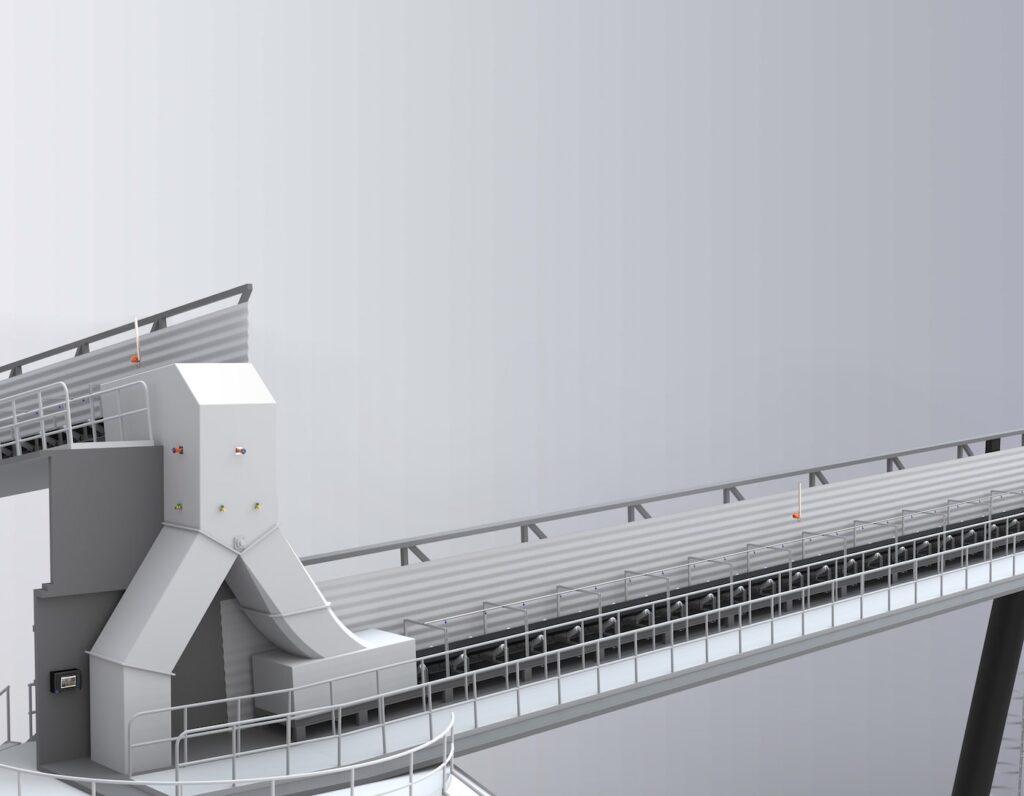

Firefly ConveyorGuard™

A fire in a belt conveyor is often hard to extinguish and can spread very quickly. In the worst case it can spread to surrounding material stacks and could last for weeks, causing major loss of revenue and production downtime.

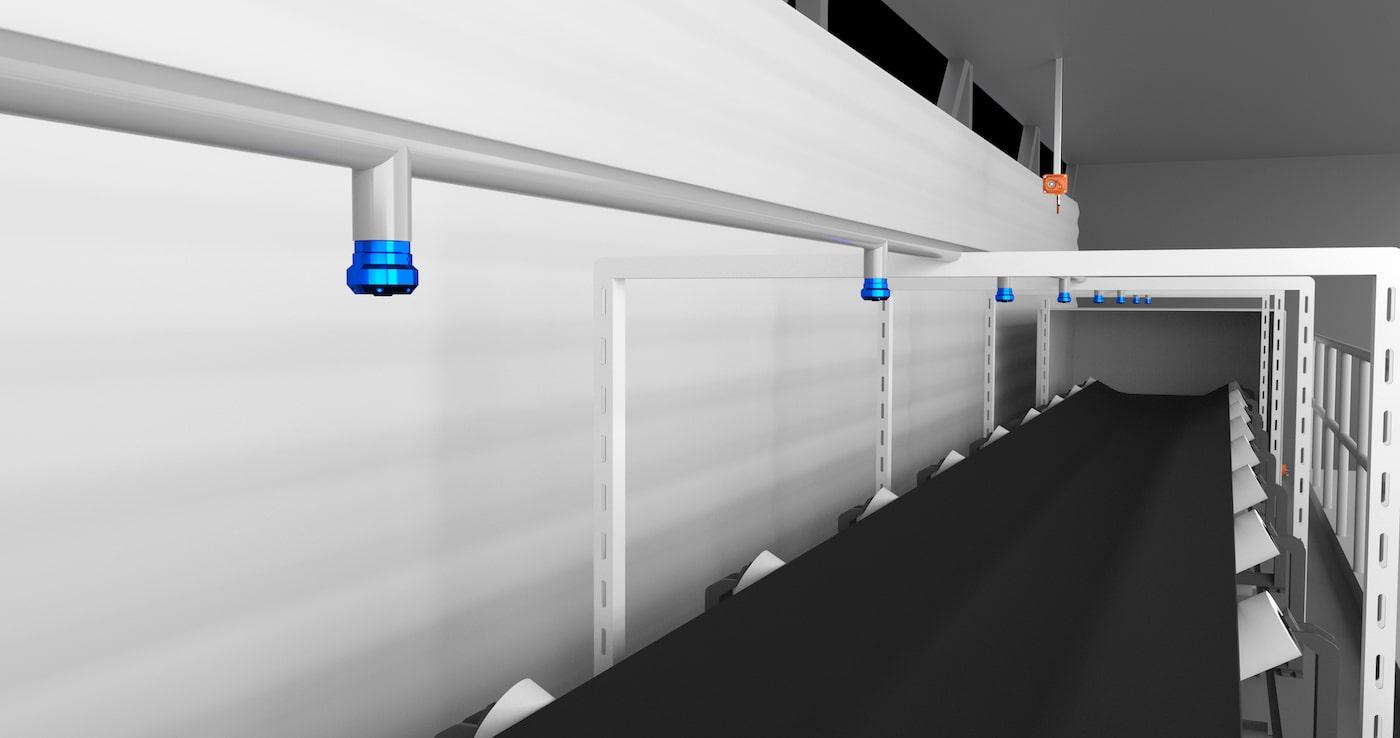

The purpose of the Firefly ConveyorGuard™ solution is to automatically detect and suppress a fire at an early stage and to stop the conveyor belt as quickly as possible. The Firefly ConveyorGuard™ solution can be complemented with Firefly open area flame detectors and/or LTS cable.

Key benefits

Quick System Response Time

Minimum Water Usage

Third Party Approved System

Precision Detection

Safe and certified for your industry. Read more about our certifications and approvals here.

Unique Fire Protection Solutions for the port industry

ULTRA QUICK SYSTEM RESPONSE TIME

The Quick Suppression System, which is part of our protection solution for shredders, operates with high performance flame detectors for extremely quick detection. The efficient water mist system has remarkable suppression capabilities which reduce damages on machinery.

PRECISION DETECTION

The True IR Spark detectors enable Precision Detection of ALL types of ignition sources such as hot black particles, glowing embers and sparks. The detectors are insensitive to daylight. Systems are also equipped with Multi-Channel flame detectors, using advanced algorithms for Precision Detection of flames with high immunity to false positives.

EXCELLENT SUPPRESSION CAPABILITIES

The Water Mist System with fire-tested and verified extinguishing capabilities utilizes very small amounts of water resulting in less impact on machinery, minimized production loss and down time.

FULL-CONE WATER SPRAY EXTINGUISHING

Powerful extinguishing with a unique nozzle design and placement aimed to penetrate and cover the entire material flow. Activated within milliseconds after detection.

Downloads

Firefly port and logistical terminals

Firefly ConveyorGuard™

Keeping industry leaders safe