Fire protection for the food industry

Ensuring safety in baking – why protection matters

Baked goods undergo exposure to high temperatures within ovens. Given that the ignition temperatures of nearly all baked products closely align with the average operational temperature of ovens, an inherent and constant risk exists wherein these products may succumb to combustion. This risk intensifies due to the buildup of grease, oil, crumbs, and dust, coupled with the possibility of temperature control malfunctions and oven maintenance issues. The consequence of such risks includes overheating of baked goods or the emergence of flames in and around the oven, resulting in potential disruptions to the production process, compromised product quality, and even fire hazards in storage areas.

Firefly presents a proactive protection solution designed to enhance safety within the baking industry, offering a means to mitigate risks and save substantial costs by averting potential downtime caused by fires and ensuring efficient operations.

440°C

the ignition temperature of wheat flour in a dust cloud

48%

of dust fires and explosions involve food products

Elevating safety in food industry processes

The food industry contains a wide range of processes, many containing fine and dry materials in combination with high temperatures. Materials can ignite within the process causing fires with damage to plants and production loss as a result. At Firefly, we address this critical issue by providing advanced systems that detect heat sources within machinery, process streams, and open areas surrounding equipment. Our proactive approach involves the rapid deployment of water mist to extinguish emerging fires, preventing damage to plants, and minimizing production losses.

Raising awareness for dust explosion prevention

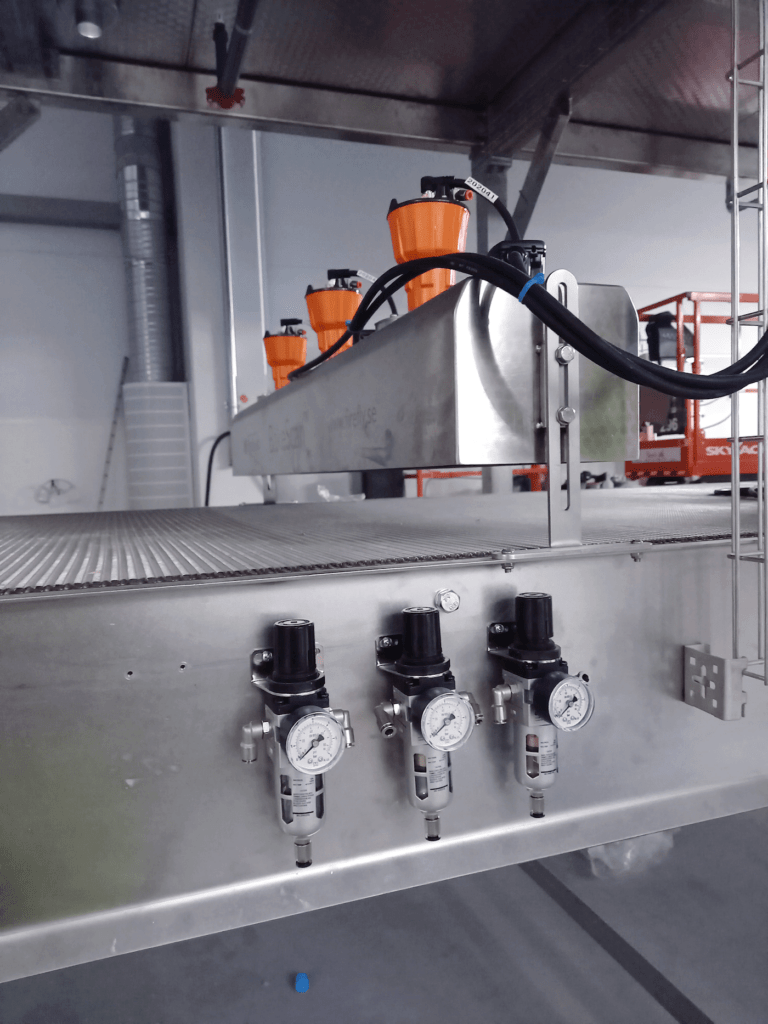

Adherence to stringent standards governs the design of various food processing machinery, and our systems align seamlessly with these regulations. Engineered with components in stainless steel and other materials tailored for food industry operations, Firefly ensures compliance with industry standards.

Our commitment to fire protection is evident through our Spark Detection and Quick Suppression Solutions, employing advanced IR-radiation and flame detection technologies in tandem with water spray extinguishing and water mist suppression.

The wake-up call for the European food industry came in 1997 with the catastrophic explosion and collapse of a 40-meter-high grain silo in Blaye, France, claiming 11 lives. Similarly, the 2008 explosion at the Imperial Sugar Company in Port Wentworth, Georgia, served as a meaningful reminder for North American food industry stakeholders. This incident resulted in a devastating fire, claiming 14 lives, and injuring 38 others. These tragic events underscore the critical importance of proactive measures to prevent combustible dust hazards.

Combustible hazards in the food industry – flour and sugar dust explosions

Food items stand as significant contributors to combustible dust fires and explosions, with a notable 48% involvement in such incidents in 2020, as reported by the US-based organization Dust Safety Science.

Within the food industry, various common materials possess the potential to generate combustible dust, leading to explosions with exceptionally high energy. Consider the following examples:

- Wheat flour, with an ignition temperature of 440°C in a dust layer and 440°C in a dust cloud.

- Sugar, powdered, with an ignition temperature of 370°C in a dust layer and 400°C in a dust cloud.

It’s crucial to note that these common food items exhibit relatively low ignition temperatures, especially considering that items below 650°C are not visibly perceived as glowing to the human eye. This underscores the inherent risk associated with combustible dust in the food processing environment.

Custom solutions for the food industry

Firefly BakeScan™

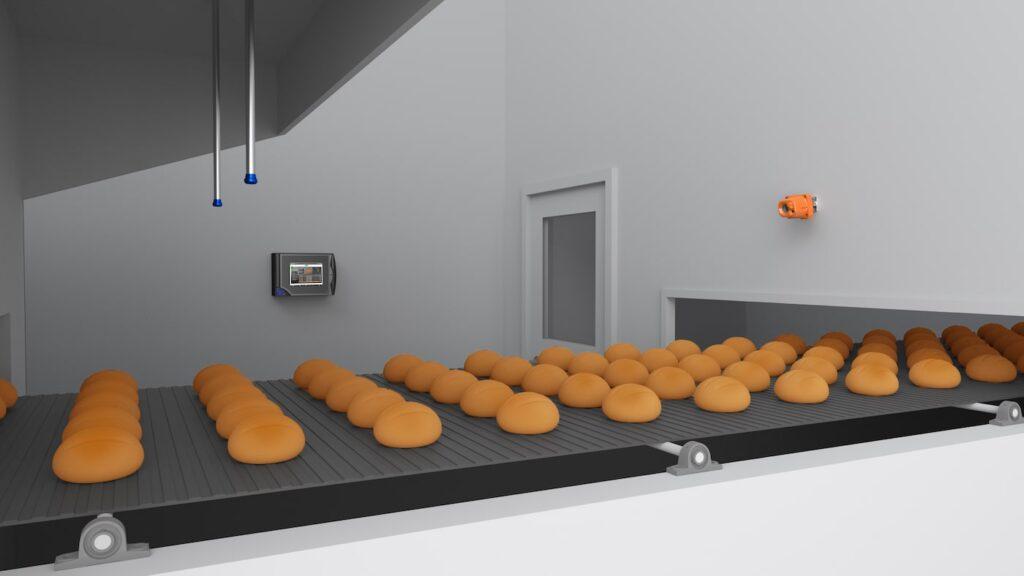

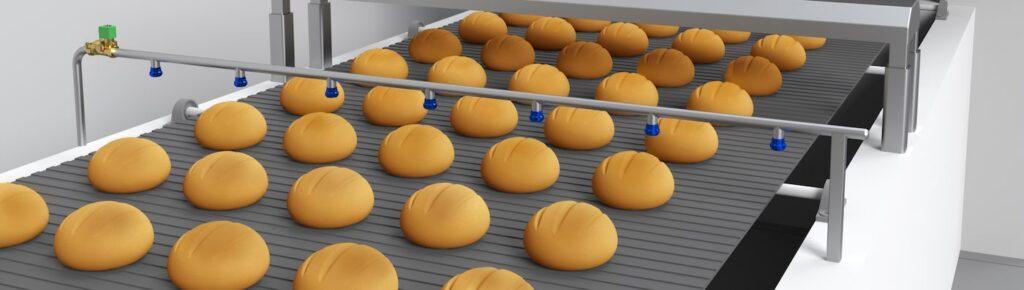

Firefly BakeScan™ solution is designed to detect overheated, glowing or burning products on transport bands of baked products being transported out from the oven, for example biscuits, tortillas, baked crisps, bread and cereals.

The system can be completed with quick acting water mist suppression. Water mist suppression enables the process to continue without warping the belt and avoids temperature stress on the cooling belts which can be very expensive to replace.

The Firefly BakeScan™ solution is an extremely flexible system and can be adapted to any process within the baking industry.

Firefly OvenGuard™

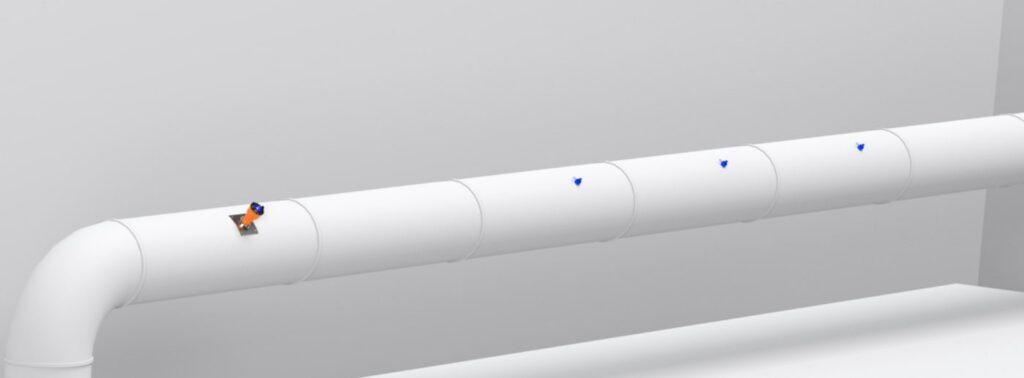

Firefly OvenGuard™ solution is designed for early detection and suppression of fire problems in the oven, at the outlet of the oven, and to suppress embers and flames in the extraction ducts. This by using a full automatic, high speed detection and suppression system. Both quick acting water mist suppression and full-cone water spray extinguishing can be used depending on the system design.

The Firefly OvenGuard™ system is extremely fast and the systems are designed to provide optimal safety against fire with minimal effect on machinery or production. The Firefly system is flexible and from a range of unique products the solutions are customized for each application.

Key benefits

Quick System Response Time

Minimum Water Usage

Third Party Approved System

Precision Detection

Safe and certified for your industry. Read more about our certifications and approvals here.

Unique Fire Protection Solutions for the food industry

ULTRA QUICK SYSTEM RESPONSE TIME

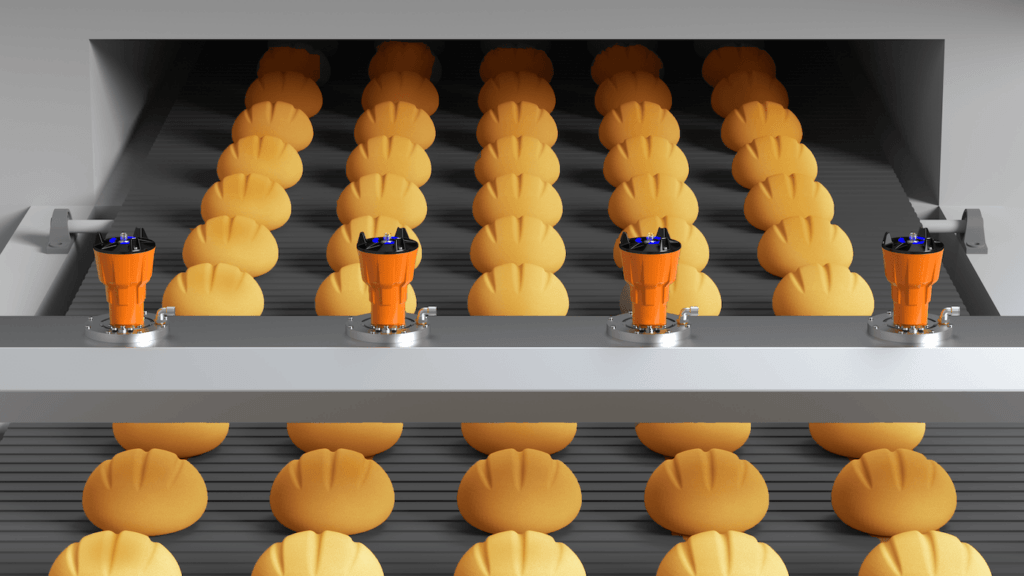

Firefly’s BakeScan™ solution is a Quick Suppression System designed to detect and extinguish glowing pieces and flames on transportation belts of baked product processes, including biscuits, tortillas, baked crisps, and cereals.

FULL-CONE WATER SPRAY EXTINGUISHING

Powerful extinguishing with a unique nozzle design and placement aimed to penetrate and cover the entire material flow. Activated within milliseconds after detection.

PRECISION DETECTION

The True IR Spark detectors enable Precision Detection of ALL types of ignition sources such as hot black particles, glowing embers, and sparks. The detectors are insensitive to daylight. Systems are also equipped with Multi-Channel flame detectors using advanced algorithms for Precision Detection of flames with high immunity to false positives.

EXCELLENT SUPPRESSION CAPABILITIES

The Water Mist System with fire-tested and verified extinguishing capabilities utilizes very small amounts of water resulting in less impact on machinery, minimized production loss and down time.

Downloads

Firefly BakeScan™ and OvenGuard™

Firefly spark detection

Firefly EXsolvo®

Firefly EXIMIO™

Keeping industry leaders safe