Fire protection for the hygiene indudstry

Addressing fire risks in absorbent material manufacturing

Absorbent materials like diapers and sanitary products, made from treated wood pulp in a vacuum process, create a volatile mix with air. Elevated temperatures can trigger high-energy fires within this airflow laden with wood dust. Ignition sources pose a risk of igniting stored products or accumulated dust, leading to devastating fires, production halts, and costly damages.

To prevent such incidents, it’s vital to detect and extinguish sparks or hot particles generated by machinery. Firefly offers tailored solutions to intercept these hazards before they reach filters, swiftly neutralizing them with CO2, water, or altering airflow.

By prioritizing proactive fire safety, companies can protect their operations, ensuring uninterrupted production and minimizing downtime.

270

degrees C – ignition temperature of a layer of cellulose

480

degrees C – ignition temperature of a cloud of cellulose

Navigating dust explosion risks in manufacturing

Dust explosions pose a significant threat when combustible particles disperse in the air, leading to substantial damage and potential fires. In industries like baby diaper manufacturing, where pulp is suctioned onto polymer films via vacuum systems similar to dust extractors, the risk is particularly acute.

Understanding dust ignition is crucial: while cellulose layers ignite at 270°C, cellulose dust clouds ignite at a 480°C, with even lower temperatures potentially triggering fires. Factors such as overfeeding in mills or equipment malfunctions can serve as ignition sources, posing serious risks to both product and plant safety.

Custom solutions for the hygiene industry

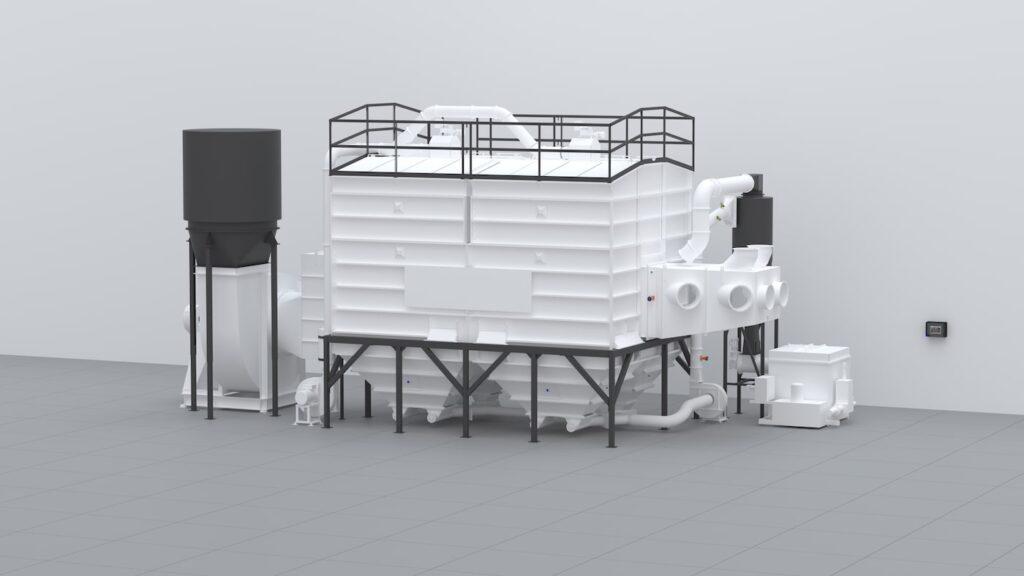

A fire on a processing line for absorbent materials can progress with extreme speed. To prevent substantial fire damage and lengthy shutdown, the source of the ignition needs to be identified and extinguished quickly.

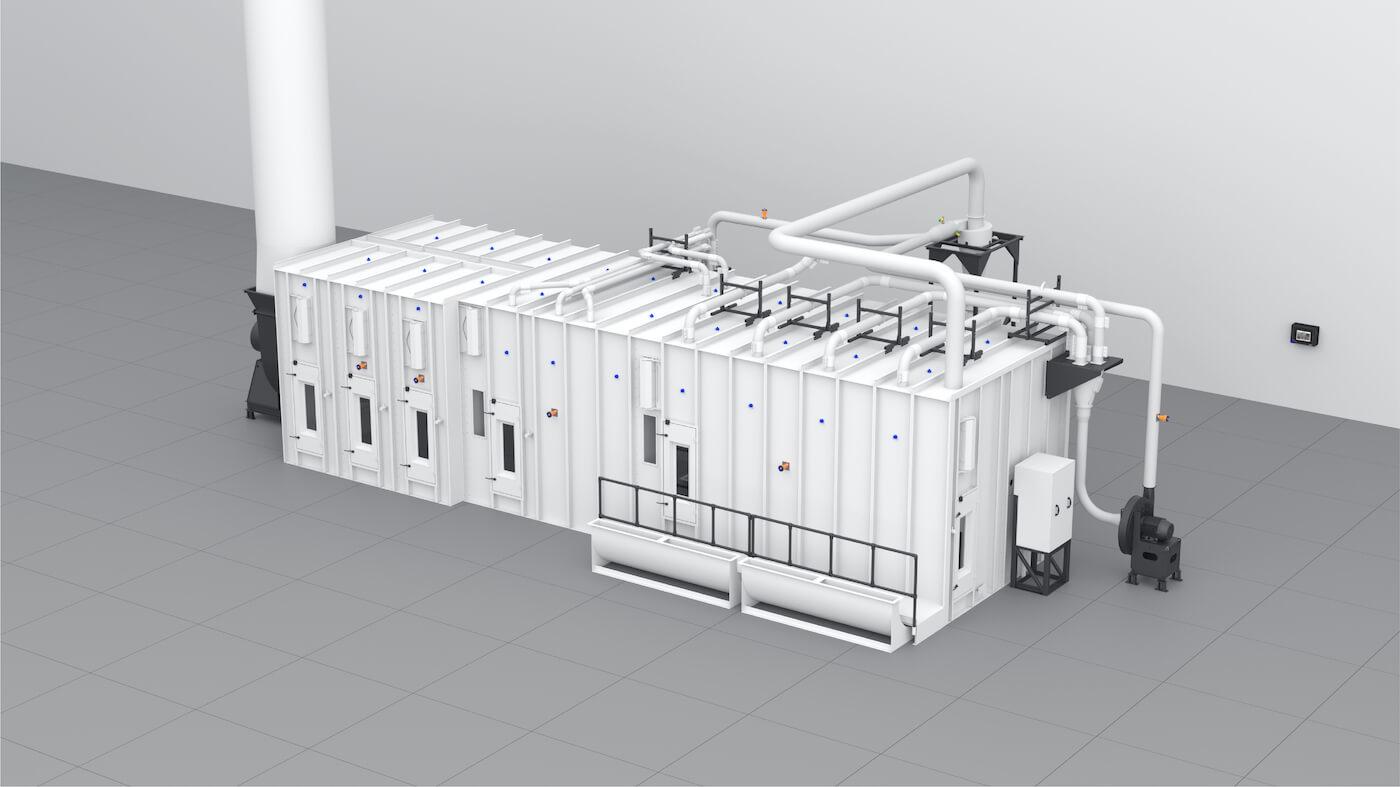

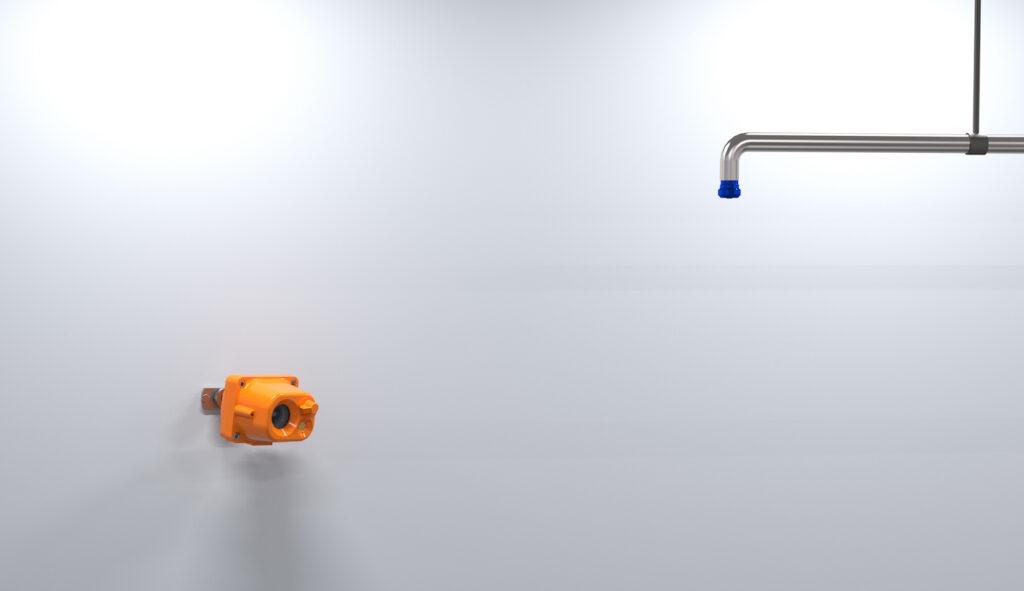

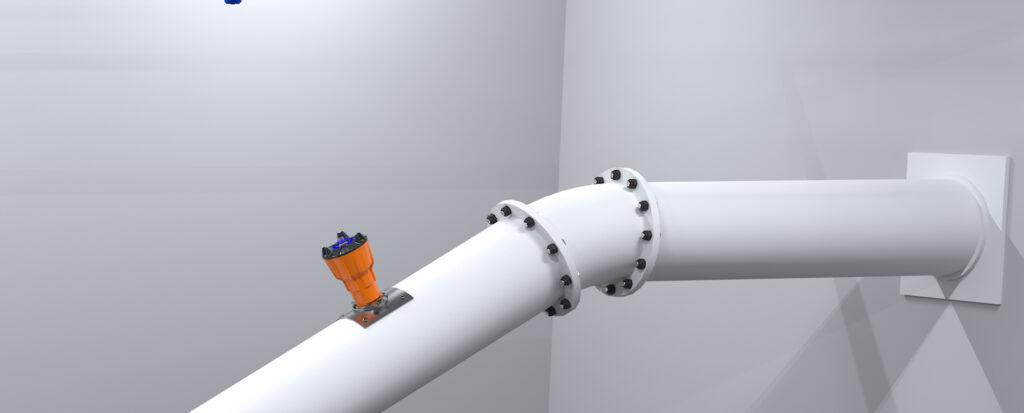

Firefly protects the facility by detecting sparks and hot particles before they reach the filter, using IR-radiation detection and extinguishing with CO2, isolation, water, or diverting the airflow.

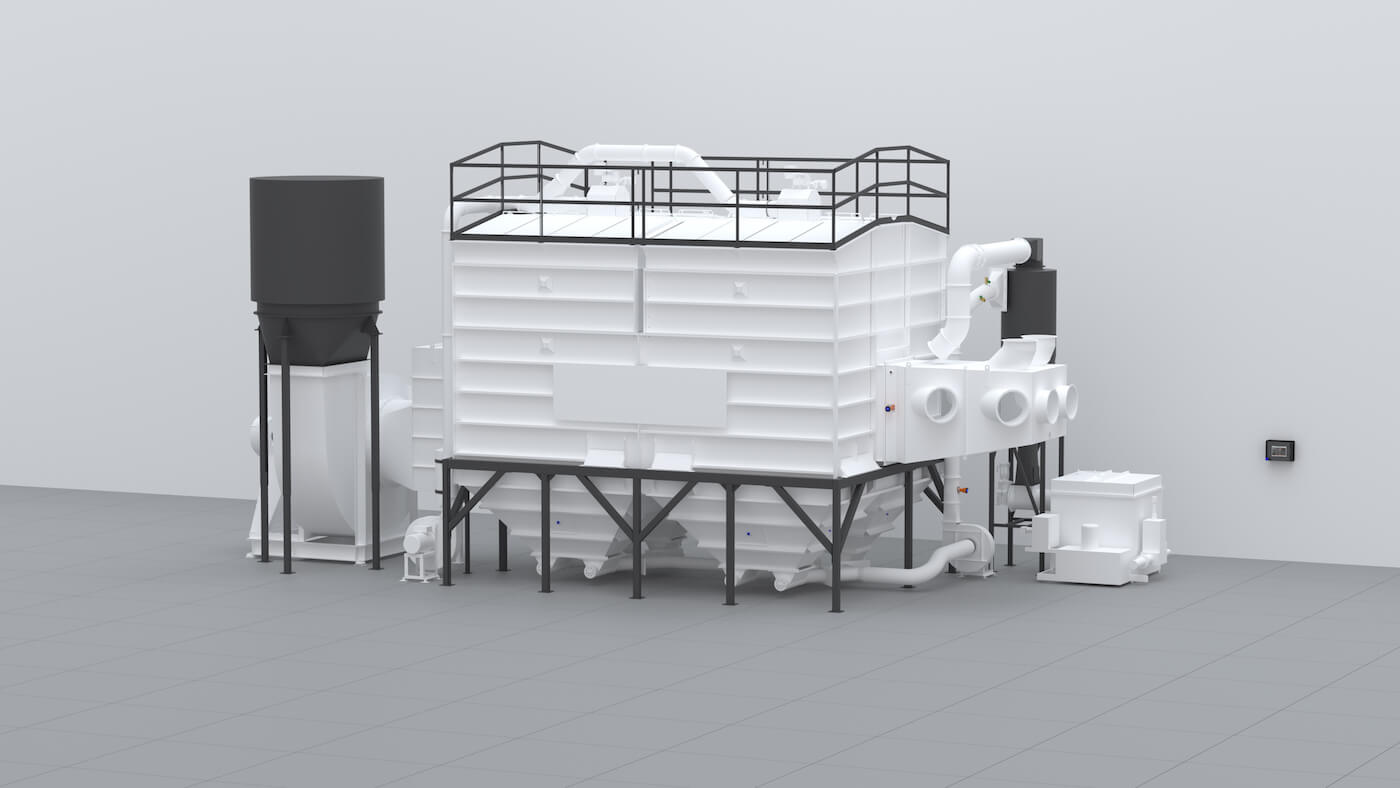

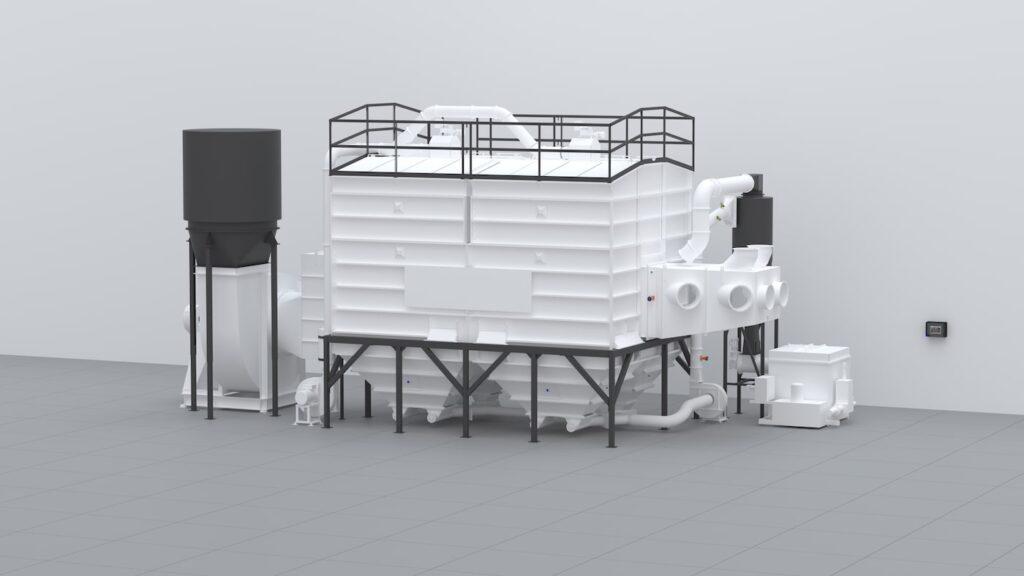

Premium filter manufacturers have succeeded to develop filter systems with sharply reduced or even eliminated risk of dust explosions, but the risk of fire still remains. A Firefly Quick Suppression System is designed for ultra-fast detection and suppression of fires in high risk areas, such as filters and mill rooms.

The Firefly Quick Suppression System for filters is based on optical flame detectors that will quickly detect flames inside the filter. The flame detectors are optimized for the dusty environment inside the filter, they have 180 degree view angle in all directions, are highly sensitive to flames, and are insensitive to daylight.

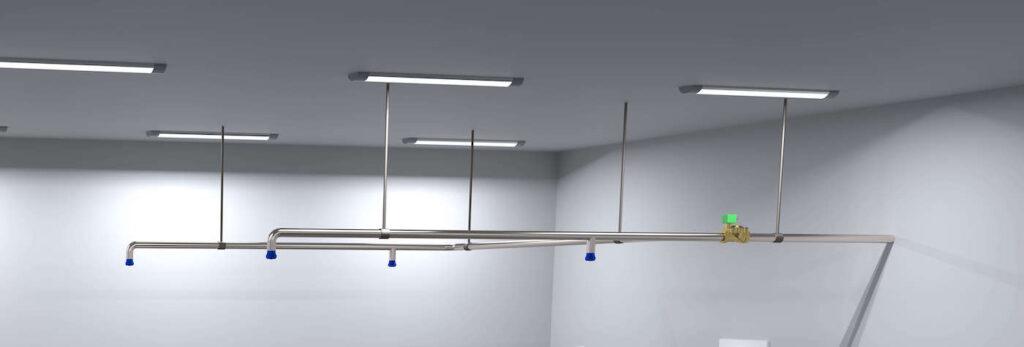

The detection is combined with a non-invasive, quick acting low pressure water mist suppression system. The Firefly water mist is designed to efficiently suppress flames with a minimal usage of water.

Key benefits

Quick System Response Time

Minimum Water Usage

Third Party Approved System

Precision Detection

Safe and certified for your industry. Read more about our certifications and approvals here.

Unique Fire Protection Solutions for the hygiene industry

ULTRA QUICK SYSTEM RESPONSE TIME

The Quick Suppression System, which is part of our protection solution for shredders, operates with high performance flame detectors for extremely quick detection. The efficient water mist system has remarkable suppression capabilities which reduce damages on machinery.

PRECISION DETECTION

The True IR Spark detectors enable Precision Detection of ALL types of ignition sources such as hot black particles, glowing embers and sparks. Systems are also equipped with Multi-Channel flame detectors using advanced algorithms for Precision Detection of flames with high immunity to false positives.

EXCELLENT SUPPRESSION CAPABILITIES

The Water Mist System with fire-tested and verified extinguishing capabilities utilizes very small amounts of water resulting in less impact on machinery, minimized production loss and down time.

FIREFLY FILTER PROTECTION

Dust extraction systems are vital to take care of dust generated in dry bulk handling processes. The risk in these units is considered very high due to the high concentration of dust. Firefly’s FM-approved Spark Detection and Extinguishing System will efficiently prevent ignition sources from entering the risk zones.

Downloads

Firefly diaper and personal hygiene solutions

Firefly EXIMIO™

Firefly spark detection

Firefly quick suppression

Firefly MGD

Keeping industry leaders safe