Fire protection for the pulp and paper industry

Optimize paper and pulp operations for continuous efficiency

In the paper and pulp manufacturing sector, the seamless flow of operations is crucial. Unfortunately, frequent fires pose significant disruptions and costs to these processes. As production scales, the risk of fire incidents and explosions escalates, impacting both productivity and safety.

Flash dryers and slab presses stand out as high-risk areas within pulp factories, prone to fire outbreaks and dust explosions. Addressing these vulnerabilities is essential for enhancing operational safety and efficiency in the paper and pulp industry.

281

dust fires and explosions recorded in US industry over 25-year period

24%

of all dust fires and explosions are due to wood and paper dust

Optimizing fire safety in paper mills: identifying high-risk areas

Paper mills contain several areas prone to fires or explosions, such as IR-dryers, mills, and filters. If a fire breaks out, it can quickly spread, causing significant damage to the machinery and the facility.

IR-dryers, found in both paper and packaging industries, are common sources of fires in paper mills. When accidents occur, they can lead to lengthy and expensive production halts.

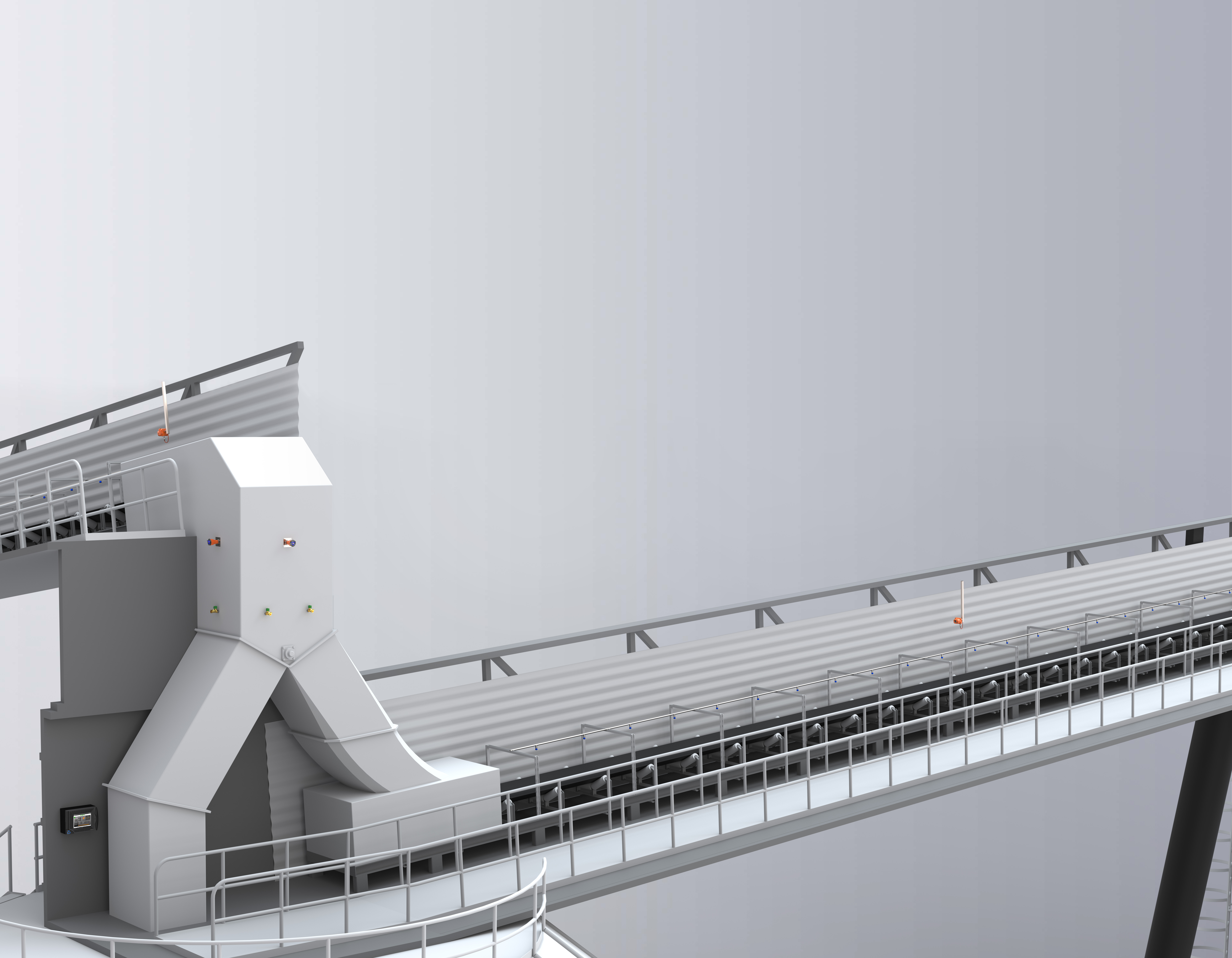

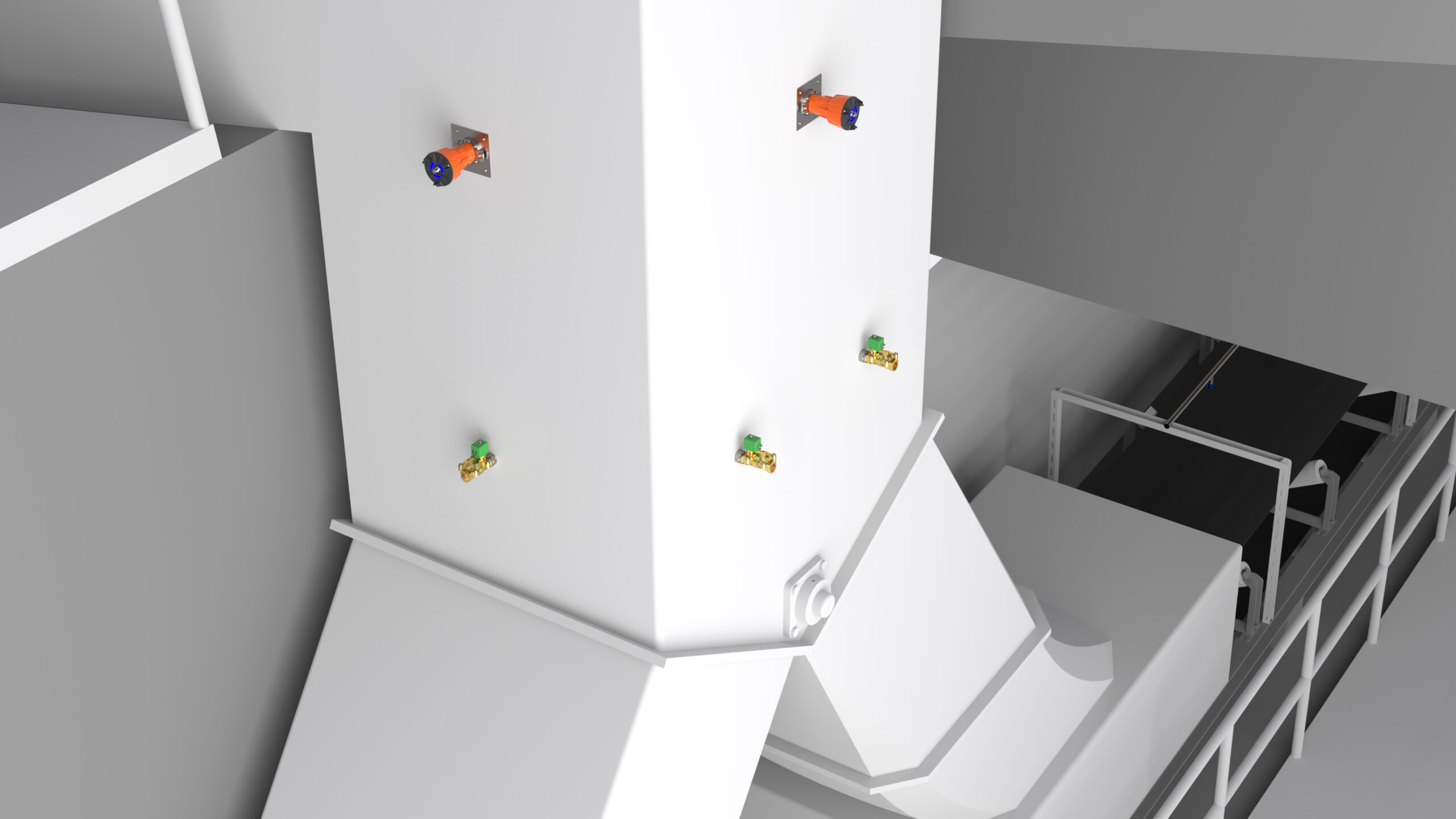

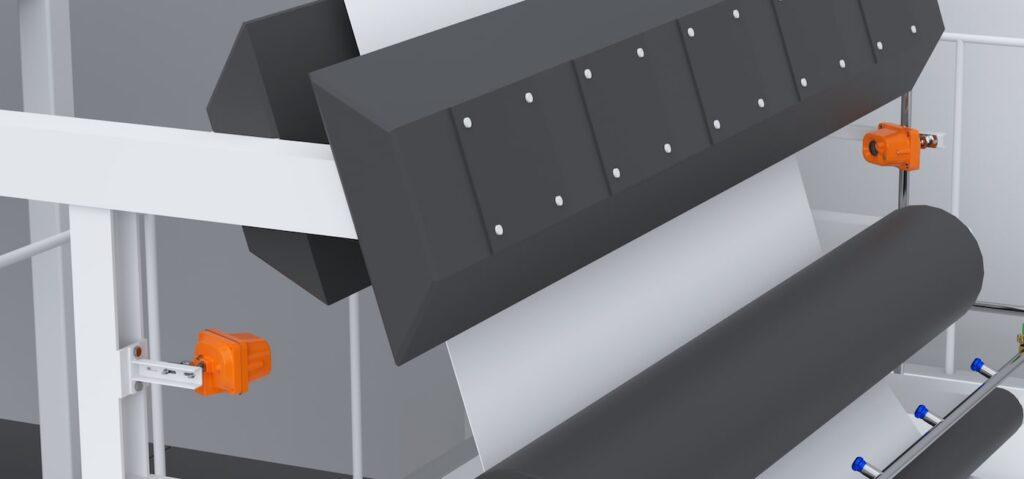

Additionally, in pulp factory yards, the long conveyors that move wood chips pose another significant fire risk. Overheating damaged bearings can ignite the wood chips, potentially causing widespread damage throughout the factory. Implementing effective fire safety measures in these areas is crucial to prevent accidents and protect both employees and assets.

Avoid unnecessary downtime

Within an integrated pulp and paper mill, the largest paper machine typically embodies the most substantial value concentration. Often, multiple paper machines are housed within the same facility. However, in the unfortunate event of a fire necessitating machine replacement, the prolonged delivery times, exceeding 18 months, become a considerable challenge. Furthermore, a prolonged start-up period is imperative before achieving full production capacity.

According to the US Chemical Safety Board, at least 281 combustible dust fires and explosions occurred in various industries across the US between 1980 and 2005. Remarkably, 24% of these incidents were linked to wood and paper dust.

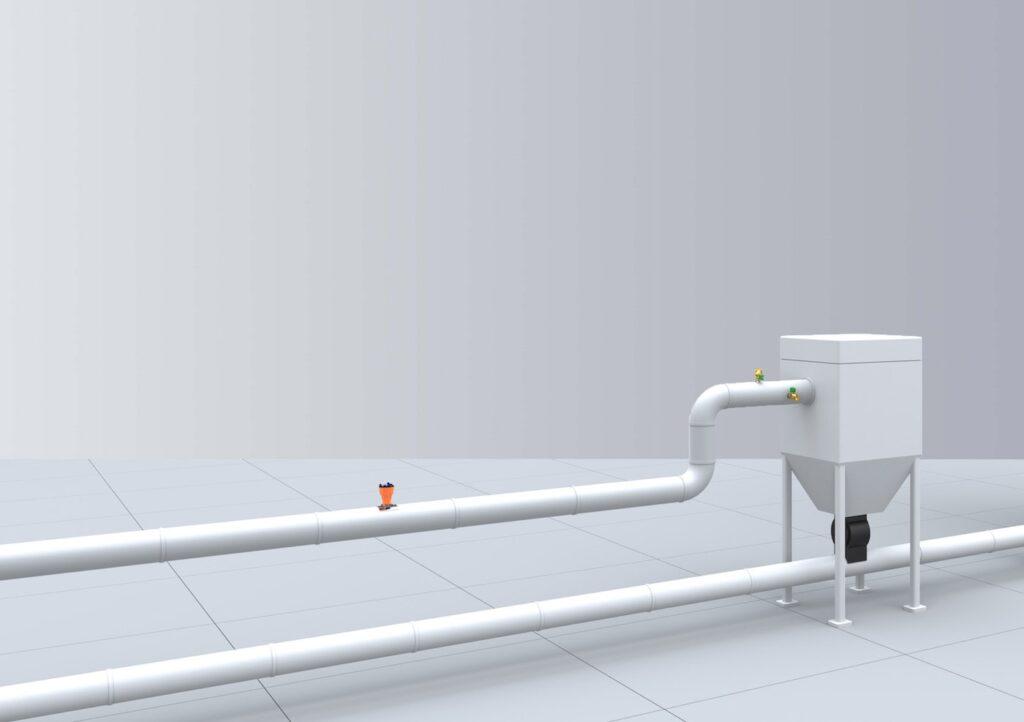

Firefly specializes in detecting heat sources within the manufacturing process, whether inside machines or in open areas surrounding them. By swiftly identifying these heat sources, potential damage to the plant can be averted, ensuring uninterrupted processes and minimizing downtime.

Custom solutions for the pulp & paper industry

Firefly IR-Guard™

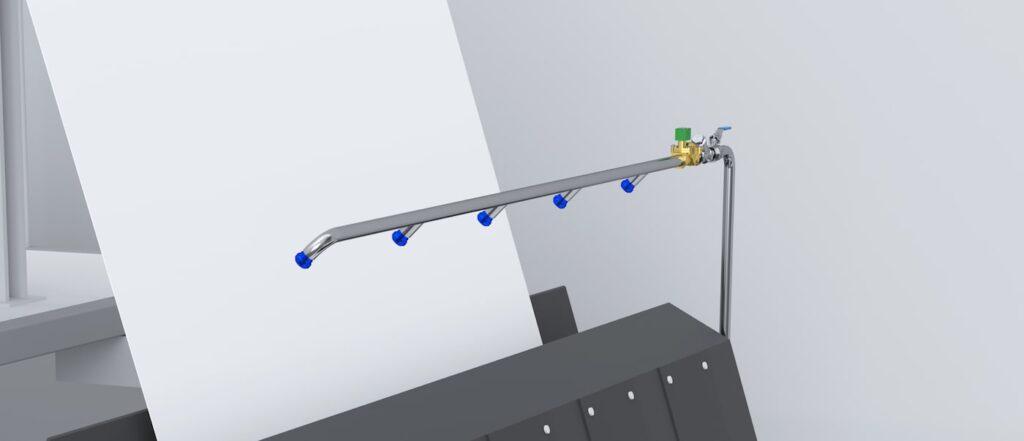

Firefly protects mills and filters with infrared detection of sparks and hot particles. Heat sources are extinguished using water spray, CO2 or water mist suppression.

Firefly’s IR-Guard™ solution is a Quick Suppression System and includes quick flame detection and water mist suppression, providing optimal protection of one of the most valued links in the production chain.

Firefly protects paper mills and filters with IR-radiation detection of sparks and hot particles and extinguish using water spray, isolation with CO2 or water mist suppression.

Key benefits

Quick System Response Time

Minimum Water Usage

Third Party Approved System

Precision Detection

Safe and certified for your industry. Read more about our certifications and approvals here.

Unique Fire Protection Solutions for the pulp & paper industry

ULTRA QUICK SYSTEM RESPONSE TIME

The Quick Suppression System, which is part of our protection solution for shredders, operates with high performance flame detectors for extremely quick detection. The efficient water mist system has remarkable suppression capabilities which reduce damages on machinery.

PRECISION DETECTION

The True IR Spark detectors enable Precision Detection of ALL types of ignition sources such as hot black particles, glowing embers and sparks. Systems are also equipped with Multi-Channel flame detectors using advanced algorithms for Precision Detection of flames with high immunity to false positives.

EXCELLENT SUPPRESSION CAPABILITIES

The Water Mist System with fire-tested and verified extinguishing capabilities utilizes very small amounts of water resulting in less impact on machinery, minimized production loss and down time.

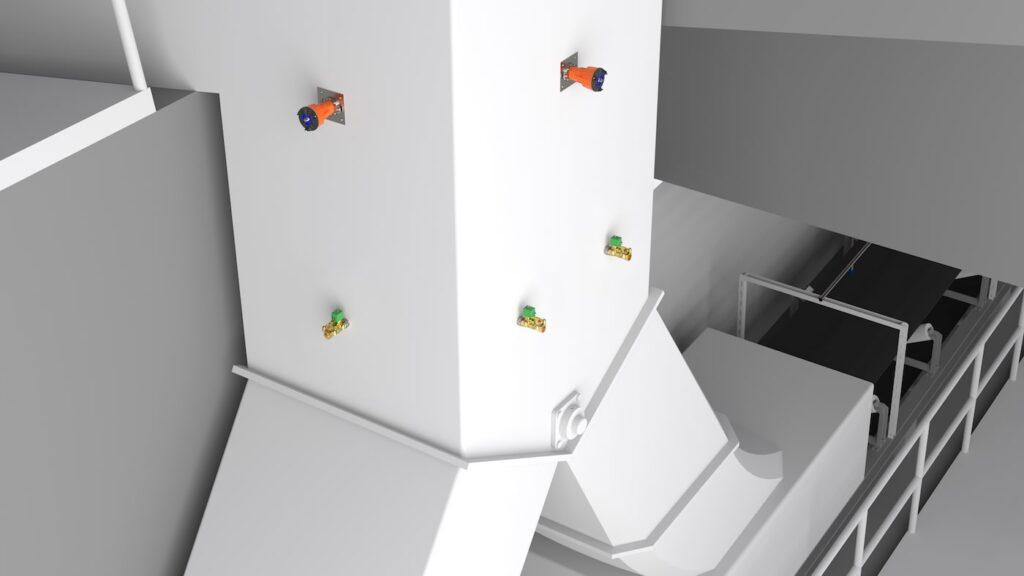

FIREFLY FILTER PROTECTION

Dust extraction systems are vital to take care of dust generated in dry bulk handling processes. The risk in these units is considered very high due to the high concentration of dust. Firefly’s FM-approved Spark Detection and Extinguishing System will efficiently prevent ignition sources from entering the risk zones.

Downloads

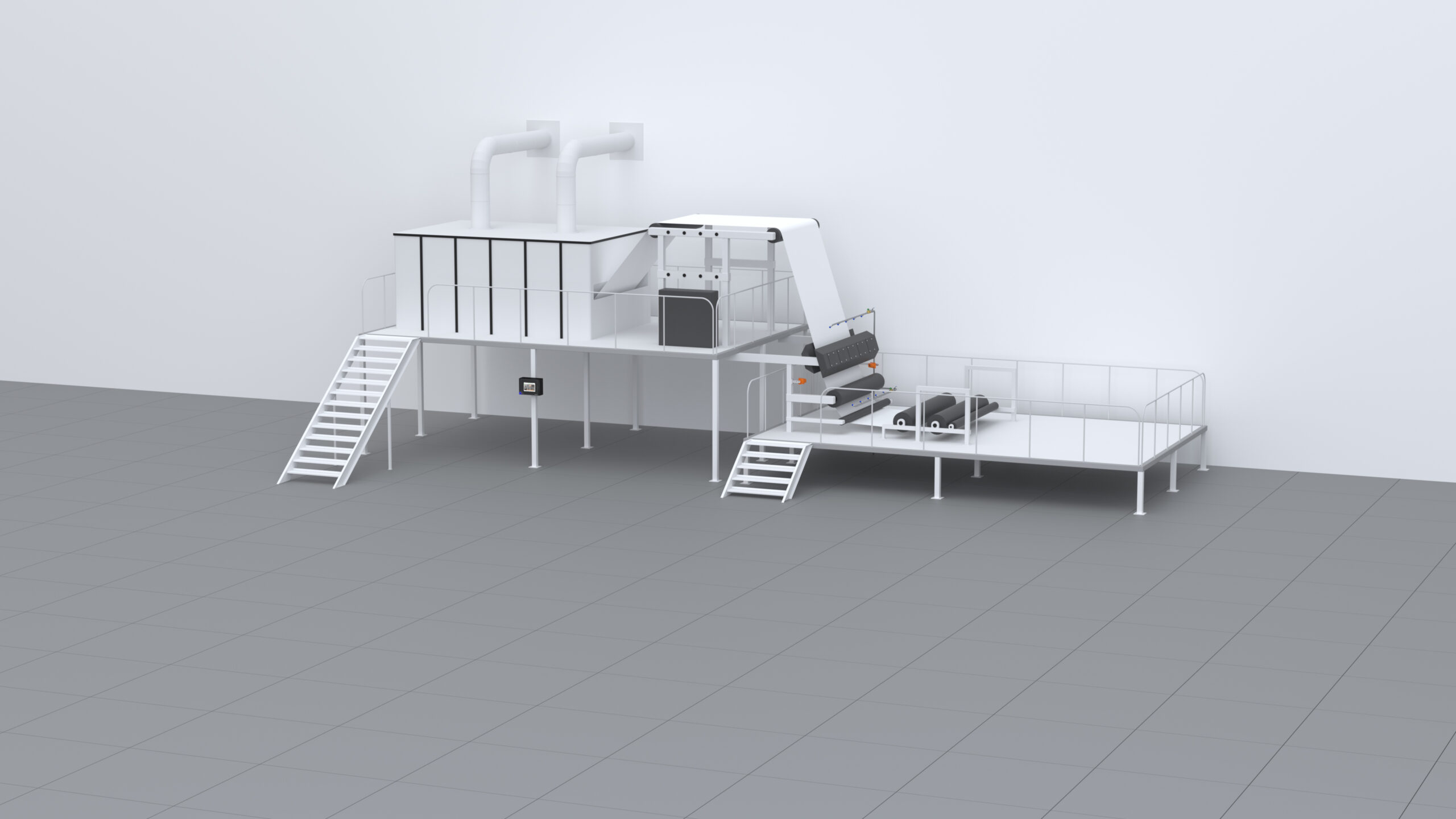

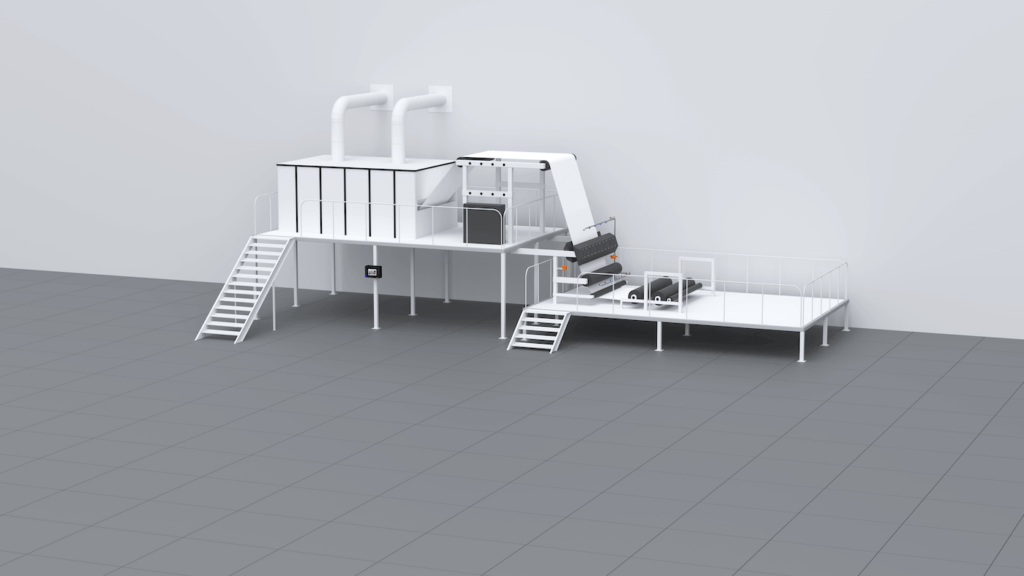

Firefly ConveyorGuard™

Firefly EXIMIO™

Firefly Spark Detection System

Firefly Quick Suppression System

Keeping industry leaders safe